Why Basement Wall Cracks Demand Your Attention

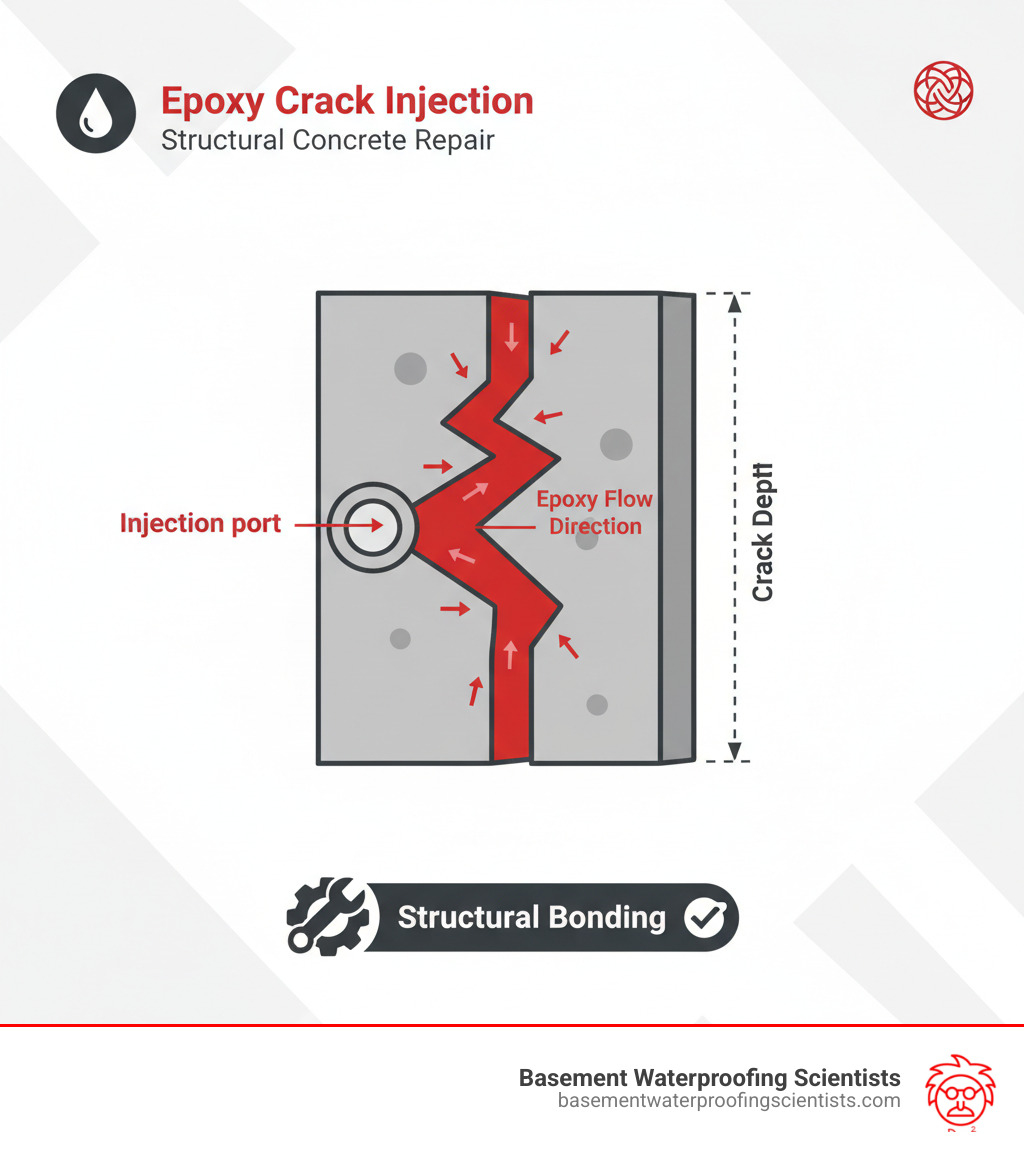

Epoxy crack injection is a high-pressure repair method that fills concrete cracks with a strong, two-part resin to restore structural integrity and prevent water intrusion. Here’s what you need to know:

- What it does: Bonds crack faces together, restoring original concrete strength

- Best for: Static (non-moving) cracks in poured concrete foundations

- How it works: Epoxy resin is injected under pressure through ports, filling the crack from the inside out

- Key benefit: Creates a waterproof seal stronger than the concrete itself

- When to use it: For structural repairs, not just cosmetic fixes

That hairline crack in your basement wall might seem harmless, but it could be a sign of a larger issue. While some minor cracks are suitable for a DIY fix, others indicate serious structural problems that require a professional. The key is knowing the difference before you invest time and money in a repair that might not hold.

Concrete cracks due to drying shrinkage, thermal movement, soil settlement, or hydrostatic pressure. When water penetrates these cracks—even those as narrow as 0.002 inches—it can lead to mold, corrode rebar, and weaken your home’s foundation.

Epoxy crack injection is the gold standard for structural repair because it doesn’t just fill a gap; it creates a bond stronger than the concrete itself. However, achieving this result requires the right materials, technique, and equipment.

I’m Darin Garvey, and with over 30 years in the basement waterproofing industry, I’ve seen the results of both successful and failed DIY repairs. Understanding the fundamentals of this method is crucial for making an informed decision to protect your home.

What is Epoxy Crack Injection and Why Use It?

Think of epoxy crack injection as structural surgery for your foundation. Instead of a surface patch, this method heals the crack from within, bonding the concrete back together.

The process uses a two-part epoxy resin system. When mixed, the components trigger a chemical reaction, changing the liquid into a solid that is stronger than the original concrete. During high-pressure injection, this resin is forced deep into the crack, filling every microscopic void. This creates a structural bond that restores the foundation’s tensile strength (its ability to resist pulling forces) and forms a permanent moisture barrier.

This method is ideal for static, non-moving cracks where the goal is a permanent structural repair. It is not intended for active cracks that are still shifting due to ongoing foundation settlement.

For a deeper dive, the American Concrete Institute offers a technical guide on structural crack repair. Our guide on Understanding Structural Basement Repair: What You Need to Know also covers the full spectrum of issues we see in Pennsylvania, New Jersey, and Delaware.

Primary Causes of Foundation Cracks

Understanding why a crack appeared is the first step to a proper repair. Foundation cracks are rarely random; they are symptoms of underlying forces. The most common causes include:

- Drying Shrinkage: As new concrete cures and excess water evaporates, it can shrink and form small hairline cracks.

- Thermal Movement: Concrete expands with heat and contracts with cold. The freeze-thaw cycles common in our region put constant stress on foundation walls, leading to cracks over time.

- Soil Settlement: The ground beneath your home can shift or compact unevenly. This “differential settlement” pulls the foundation in different directions, causing stress cracks.

- Hydrostatic Pressure: When groundwater accumulates around your foundation, it exerts immense pressure on the walls. This force can create new cracks or widen existing ones, allowing water to enter your basement.

Understanding these root causes is key to selecting the right repair method. For practical advice on managing minor issues, check out our Small Foundation Cracks Homeowner Tips.

Advantages Over Other Repair Methods

While surface patches and hydraulic cement offer a temporary fix, epoxy crack injection provides a permanent, structural solution with several key advantages:

- Structural Restoration: Unlike cosmetic patches, epoxy injection welds the concrete back together, restoring its original strength. The repaired area is often stronger than the surrounding concrete.

- Superior Waterproofing: The high-pressure injection process fills the entire depth of the crack, creating an impenetrable barrier against moisture—critical in areas like Philadelphia and Reading with high water tables.

- Long-Term Durability: Cured epoxy is a rigid solid that won’t shrink, crack, or degrade over time. It resists chemicals, moisture, and temperature changes that cause other materials to fail.

- Prevents Rebar Corrosion: By creating a watertight seal, epoxy injection stops water from reaching the steel rebar inside your foundation, preventing rust and the expansive forces that lead to further cracking.

For a complete comparison of repair methods, our Basement Wall Crack Repair Guide walks you through all the options.

The DIY vs. Professional Epoxy Crack Injection Process

While the fundamental steps of epoxy crack injection are the same for a DIYer or a professional, the difference lies in the diagnosis, equipment, and experience. Understanding the process helps you decide whether to tackle it yourself or call in an expert.

Step 1: Crack Assessment and Preparation

Proper preparation is critical for a lasting repair. First, the crack must be diagnosed. Is it static (stable) or active (still moving)? Epoxy injection is only suitable for static cracks.

Next, the surface must be thoroughly cleaned. Using a wire brush and vacuum, remove all dirt, dust, loose concrete, and any white, powdery efflorescence from the crack and the surrounding area. Epoxy bonds to clean concrete, not to contaminants, so a pristine surface is non-negotiable. For some cracks, V-grooving (widening the surface) may be necessary to ensure the epoxy and cap seal adhere to sound concrete.

For challenges specific to exterior cracks, see our guide on Fixing Exterior Foundation Cracks.

Step 2: Installing Injection Ports and Sealing the Crack

Injection ports are small plastic fittings that act as entry points for the epoxy. They are placed along the crack, typically spaced 8 inches apart, and can be surface-mounted or set into drilled holes.

Once the ports are in place, the entire surface of the crack is covered with a thick epoxy paste. This cap seal contains the injected epoxy, forcing it to fill the crack from the inside out. The seal must be strong enough to withstand injection pressure. It is crucial to let the cap seal cure completely before injecting—rushing this step can cause a blowout and ruin the repair.

Step 3: The Epoxy Crack Injection Procedure

With the prep work done, it’s time to inject. The two-part epoxy is mixed according to the manufacturer’s specifications—improper ratios will cause the repair to fail. Each batch has a limited pot life (working time) before it begins to harden.

Using a dispensing gun, injection begins at the lowest port on a vertical crack. The epoxy is injected slowly and steadily until it flows out of the port directly above it. This indicates the crack is full between those two points. The lower port is then capped, and the process is repeated up the line until the entire crack is filled. This is where professional dual-cartridge guns excel, maintaining consistent pressure and mixing for a complete fill, something difficult to achieve with basic DIY kits.

After the epoxy cures (typically 24-48 hours), the ports and cap seal are removed, leaving a permanent, structural repair. For more on epoxy applications, see our guide on How to Epoxy a Basement Floor.

Choosing the Right Materials and Tools

Precision work like epoxy crack injection demands exactly the right materials and tools. Using the wrong epoxy or equipment can compromise the repair and lead to failure.

Understanding Epoxy Resin Types and Viscosity

Not all epoxies are the same. The correct viscosity (thickness) must be chosen based on the crack’s width:

- Low-Viscosity Epoxy: A water-thin consistency (150-600 cps) designed to penetrate hairline cracks (0.010 inches or smaller).

- Medium-Viscosity Epoxy: A versatile, slightly thicker formula that flows well but has enough body for wider cracks.

- Gel-Viscosity Epoxy: A thick, paste-like consistency that won’t drip, making it ideal for very wide cracks or overhead applications.

Always choose an epoxy that meets ASTM C 881 standards, which guarantees it has been tested for strength and durability. For more on selecting materials, see our recommendations for the Best Epoxy for Basement Concrete Floor.

Essential Equipment for Epoxy Crack Injection

Achieving a professional-grade repair requires more than a simple caulk gun. The essential toolkit includes:

- Surface Preparation Tools: Wire brushes, grinders, and a shop vacuum to ensure the concrete is perfectly clean for bonding.

- Injection Ports: Plastic fittings that allow epoxy to be injected into the crack.

- Epoxy Paste Adhesive: A thick paste used to secure the ports and create the surface “cap seal.”

- Dual-Cartridge Dispensing Gun: A specialized tool that automatically mixes the two-part epoxy at the correct ratio and maintains consistent injection pressure.

- Static Mixers: Nozzles that attach to the dispensing gun to thoroughly blend the epoxy components as they are injected.

- Personal Protective Equipment (PPE): Safety goggles, chemical-resistant gloves, and a respirator are non-negotiable for handling epoxy safely.

The Role of Temperature and Safety

Temperature significantly impacts epoxy performance. Warmer temperatures decrease viscosity and shorten the pot life (working time), while colder temperatures thicken the epoxy and extend cure times. Professionals adjust their materials and techniques based on air and concrete temperature to ensure a successful repair.

Safety is paramount. Personal Protective Equipment (PPE), including safety goggles, chemical-resistant gloves, and a respirator, must be worn. Adequate ventilation is also crucial. Uncured epoxy components are considered hazardous waste and must be disposed of according to local regulations, not in household trash.

For related temperature considerations, see our guide on Applying Epoxy Paint to Concrete Floor.

Weighing the Pros and Cons: DIY Kits vs. Hiring a Pro

Deciding between a DIY kit and hiring a professional comes down to several factors. While a DIY approach can save money on minor repairs, a professional service offers expertise, guarantees, and the ability to handle complex structural issues.

| Factor | DIY Epoxy Injection Kit | Professional Service |

|---|---|---|

| Cost | $70 – $200 per kit | $4,000 – $8,000 (often part of a larger waterproofing solution) |

| Best For | Small, stable, non-leaking hairline cracks | Structural cracks, moving cracks, bowing walls, active leaks |

| Effectiveness | Variable; depends on user skill and crack condition | High; proper diagnosis and application for a permanent fix |

| Warranty | Typically none | Often a lifetime, transferable warranty |

| Time | Several hours to a full weekend, including prep and cure time | Professionals complete the job efficiently |

| Skill Level | Requires patience, precision, and comfort with chemicals | Handled by trained technicians with specialized equipment |

For more guidance on making foundation repair decisions, check out our Foundation Repair Company Philadelphia page.

When a DIY Repair is Feasible

A DIY kit can be a viable option under specific conditions. Consider this route if you are dealing with:

- Small, Stable Cracks: Hairline cracks (under 0.010 inches) that show no signs of movement or widening are good candidates.

- Minor Water Seepage: If a crack only weeps slightly during heavy rain and is not actively leaking, a DIY kit may suffice.

- Budget and Skill: If you are a confident DIYer, comfortable with detailed instructions and chemical products, and have a limited budget, a kit for an 8-10 foot crack may be a cost-effective solution.

Even for a DIY project, thorough research is essential. For perspective on other DIY repairs, our DIY Carbon Fiber Foundation Repair Tips may be useful, though it addresses a different repair type.

Why to Hire a Professional

For many situations, hiring a professional is not just recommended—it’s essential for the safety and integrity of your home.

Call a professional for:

- Accurate Structural Assessment: We don’t just see a crack; we diagnose its cause. Is it from initial settling, or is your foundation under active stress? The wrong diagnosis leads to the wrong repair.

- Moving Cracks and Bowing Walls: Horizontal cracks, widening cracks, or bulging walls are signs of serious structural pressure. These issues require comprehensive solutions like carbon fiber reinforcement, not just epoxy injection.

- Active Water Leaks: Epoxy will not bond to a wet surface. Professionals use polyurethane foam to stop active leaks first, then apply structural epoxy if needed.

- Specialized Equipment and Expertise: Our industrial-grade pumps, precision mixing tools, and range of epoxies ensure a complete, durable repair that penetrates over 75% of the crack volume.

- Guaranteed Peace of Mind: Our work comes with a lifetime guarantee. You get the assurance that the job was done right by Foundation Experts who have protected thousands of homes in the Philadelphia, Reading, and Norristown areas.

Frequently Asked Questions about Basement Crack Repair

Over our 30 years of service, we’ve answered thousands of questions about basement cracks. Here are some of the most common ones we hear from homeowners in Pennsylvania, New Jersey, and Delaware.

Is epoxy or polyurethane better for basement cracks?

Both are excellent materials, but they serve different purposes.

- Epoxy is for structural repair. It bonds the concrete together, restoring the wall’s original strength. It is ideal for static (non-moving) cracks where structural integrity is the primary goal.

- Polyurethane is for flexible sealing. It expands to fill voids and stop active water leaks. Its flexibility allows it to accommodate slight, non-structural movement in a crack.

We often use polyurethane to stop an active leak, then follow up with epoxy for a permanent structural repair.

How long does an epoxy crack repair last?

A professional epoxy crack injection is a permanent solution designed to last the lifetime of your home. The cured epoxy creates a bond that is stronger than the concrete itself.

However, the repair’s permanence depends on addressing the crack’s root cause. If underlying issues like hydrostatic pressure or soil settlement are not managed, new cracks can form elsewhere. A true professional will investigate and recommend solutions for these root causes, not just treat the symptom.

Can I inject a crack that is actively leaking water?

No, you cannot inject structural epoxy into an actively leaking crack. Epoxy requires a dry surface to bond correctly; injecting it into flowing water will result in a failed repair.

For active leaks, professionals use a two-step process. First, a water-activated polyurethane foam is injected to expand rapidly and stop the water flow. Once the leak is controlled and the area is dry, structural epoxy crack injection can be performed to restore the wall’s integrity.

If you have a leaking crack, our guide on Crack in Basement Wall Leaking Water explains how we handle these urgent situations.

Conclusion

Epoxy crack injection is more than a simple patch; it’s a structural repair that restores your foundation’s strength and creates a permanent waterproof seal. While a DIY kit may be suitable for a minor, stable hairline crack, most situations demand professional expertise.

Misdiagnosing a crack or using the wrong repair method can lead to more significant and costly problems. Issues like moving cracks, bowing walls, and active leaks require a professional assessment and specialized equipment to ensure a lasting solution.

Your home is your most significant investment. Don’t leave its structural integrity to chance. With three decades of experience serving homeowners across Pennsylvania, New Jersey, and Delaware, Basement Waterproofing Scientists has the expertise to do the job right. We provide accurate diagnoses, professional repairs, and the peace of mind that comes with a lifetime guarantee.

For a comprehensive assessment and professional foundation repair services, contact our experts today to keep your basement dry and your foundation strong.