Why the Best Sealer for Mobile Home Foundation Protection Matters More Than You Think

The best sealer for mobile home foundation protection depends on your foundation material and climate, but here are our top recommendations:

| Foundation Material | Best Sealer Type | Expected Lifespan | Best For |

|---|---|---|---|

| Concrete Slabs/Blocks | Penetrating Silane/Siloxane | 10+ years | Deep protection, breathability |

| Concrete Foundation (High Moisture) | Epoxy Sealer | 5-10 years | Water resistance, chemical protection |

| Wood Skirting | Oil-Based Wood Sealer | 3-5 years | UV protection, water repellency |

| Metal Skirting | Elastomeric/Rubberized Coating | 5-7 years | Flexibility, rust prevention |

Unlike traditional homes, mobile home foundations often have exposed crawl spaces on piers, blocks, or slabs, making them highly vulnerable to moisture from the ground up. Moisture is the enemy, leading to wood rot, rust, mold, high energy bills, and structural damage. Research shows that sealed concrete can last up to ten times longer than unsealed surfaces—a difference that directly impacts your home’s value.

The challenge is choosing the right sealer. Lifespans vary greatly, from 1-5 years for acrylics to over 10 years for penetrating sealers. Each type works differently: penetrating sealers bond within the concrete, while film-forming sealers create a surface barrier. Your climate is also a major factor; freeze-thaw regions require flexible sealers, while humid areas demand breathability.

I’m Darin Garvey, and with over 30 years at Basement Waterproofing Scientists, I’ve seen how the right sealer prevents foundation failure. Our experience in Pennsylvania, New Jersey, and Delaware proves that successful sealing starts with understanding your specific materials and environment.

Simple guide to best sealer for mobile home foundation:

Why Sealing Your Mobile Home Foundation is a Crucial Investment

Just like armor protects a knight, the right sealer protects your mobile home’s foundation. It’s a critical defense against a host of problems, a fact we’ve seen proven across Pennsylvania, New Jersey, and Delaware.

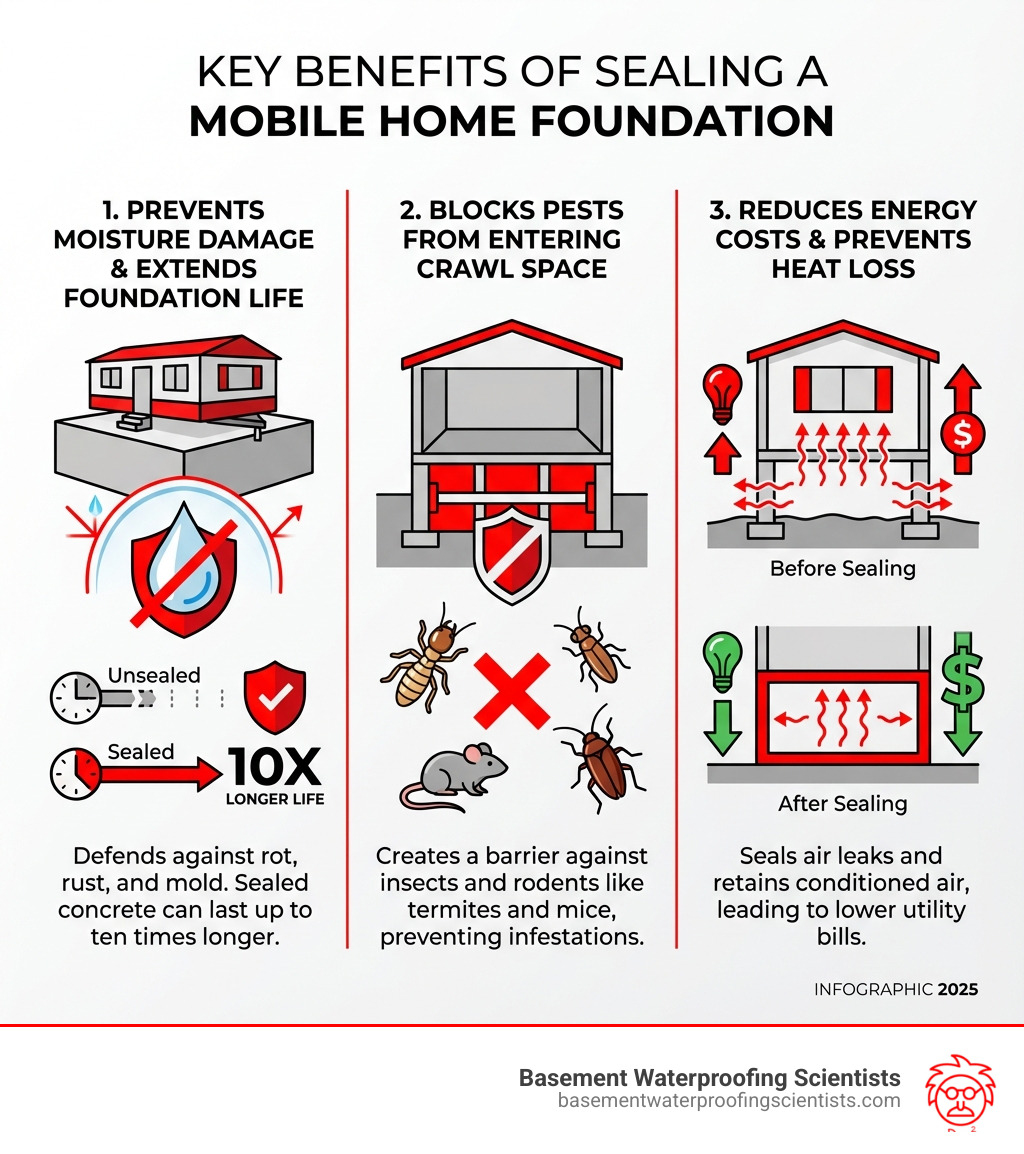

Sealing your foundation provides several key benefits:

- Prevents Moisture Damage: Unsealed foundations invite water, leading to wood rot in floor joists and rust on metal components. Moisture also creates a breeding ground for mold and mildew, which can harm indoor air quality. For more information on this topic, see the EPA’s A Brief Guide to Mold, Moisture, and Your Home.

- Deters Pests: A sealed foundation closes off the small cracks and gaps that insects and rodents use as entry points.

- Improves Energy Efficiency: Sealing air leaks in the foundation creates a better thermal envelope, reducing the workload on your HVAC system and lowering energy bills.

- Increases Home Value: By preventing costly repairs and extending the foundation’s life—sealed concrete can last up to ten times longer—you protect your home’s structural integrity and increase its property value.

Primary Concerns for Mobile Home Foundations

Mobile home foundations have unique vulnerabilities that require specific sealing strategies. Understanding these is key to effective protection.

- Hydrostatic Pressure: Water pressure from saturated soil can force moisture through porous concrete or block piers, leading to a damp crawl space.

- Freeze-Thaw Cycles: In the winters of PA, NJ, and DE, water that seeps into concrete can freeze and expand. This cycle widens cracks and causes the surface to flake (spalling), degrading the foundation over time.

- Shifting Soil: Movement in the soil can create new cracks, providing entry points for water and pests.

- Wood Rot & Metal Rust: Moisture in the crawl space is a constant threat to any wood skirting or framing, causing decay. Similarly, it leads to rust on metal components, weakening the structure.

Understanding these concerns helps us identify the right solutions. For more in-depth information on how we address these challenges, you can explore our resources on foundation repair and waterproofing services from Basement Waterproofing Scientists.

Key Benefits of a Properly Sealed Foundation

Investing in the best sealer for mobile home foundation protection offers a wealth of benefits that extend far beyond just keeping water out. It’s about creating a healthier, more durable, and more energy-efficient home environment.

First and foremost, a properly sealed foundation significantly extends its life. By protecting the concrete, wood, and metal components from the corrosive effects of moisture, freeze-thaw cycles, and general degradation, you’re essentially adding years, if not decades, to its functional lifespan. This proactive approach saves you from the headache and expense of major foundation repairs down the road.

Beyond structural integrity, sealing improves indoor air quality. When moisture is allowed to enter the crawl space, it creates ideal conditions for mold and mildew growth. These fungi release spores into the air, which can then migrate into your living spaces, triggering allergies, respiratory issues, and an unpleasant musty odor. By blocking moisture at the source, a sealed foundation helps keep your indoor air fresh and healthy.

Another significant advantage is the reduction in energy bills. An unsealed crawl space acts like a leaky sieve, allowing conditioned air to escape and unconditioned air to infiltrate. This forces your HVAC system to work harder to maintain a comfortable temperature, leading to inflated utility costs. By sealing and potentially insulating the foundation, you create a more stable temperature zone, leading to noticeable savings on heating and cooling throughout the year.

Sealing prevents costly repairs. The issues we discussed earlier—wood rot, rust, extensive cracking, mold remediation—can all be incredibly expensive to fix once they’ve taken hold. A proper sealing job is a relatively modest investment that acts as a powerful preventative measure, saving you thousands in potential future expenses. Think of it as a small upfront cost to avoid a much larger bill later.

Finally, a sealed foundation effectively deters pests like termites and rodents. These creatures are always looking for easy access points to your home, and cracks or gaps in an unsealed foundation provide just that. By closing off these entry points, you make your mobile home a much less inviting target for pests, protecting your property from damage they might cause.

For a comprehensive understanding of how to protect your entire foundation, we encourage you to read our Waterproof Your Foundation: A Comprehensive Guide.

A Deep Dive into Foundation Sealer Types

When choosing the best sealer for mobile home foundation protection, it’s helpful to understand the main categories. Sealers are generally either penetrating or film-forming.

- Penetrating Sealers (Silane/Siloxane/Silicate): These absorb into the concrete to form an internal barrier. They don’t peel or flake and are breathable, allowing moisture vapor to escape. This is crucial for preventing trapped moisture. They are a superior choice for long-term waterproofing.

- Film-Forming Sealers (Acrylic/Epoxy/Polyurethane): These create a protective layer on the surface. While durable, they can trap moisture, leading to blistering or peeling, especially in below-grade applications. They are often used for specific benefits like chemical resistance or aesthetics.

Sealers also come in water-based (low odor, easy cleanup) and solvent-based (deeper penetration, stronger fumes) formulas. For any below-grade use, breathability is critical to avoid trapping water. Always look for low VOC (Volatile Organic Compound) products for better indoor air quality.

Here’s a quick comparison of common sealer types:

| Sealer Type | Lifespan | Cost (Relative) | Best Use Case | Key Characteristics |

|---|---|---|---|---|

| Acrylic | 1-5 years | Low to Medium | Decorative concrete, light traffic, UV protection | Film-forming, UV-resistant, can yellow, requires frequent reapplication, often used for aesthetics. |

| Epoxy | 5-10 years | Medium to High | Garage floors, heavy traffic, chemical resistance | Film-forming, very durable, chemical-resistant, non-breathable, can trap moisture if applied below grade without proper prep. |

| Polyurethane | 5-10 years | Medium to High | High-traffic areas, flexible, abrasion resistance | Film-forming, flexible, good abrasion resistance, can be non-breathable, similar considerations to epoxy for below-grade. |

| Silicate/Silane/Siloxane (Penetrating) | 10+ years (often permanent for silicate) | Medium to High | Deep waterproofing, breathability, freeze-thaw protection, radon mitigation | Penetrating, breathable, permanent chemical bond (silicate), excellent for moisture and freeze-thaw, no peeling/flaking. |

Sealers for Concrete Foundations (Slabs, Blocks, Piers)

For concrete elements, a penetrating sealer is typically the best choice for deep, lasting protection.

- Penetrating Silane/Siloxane: Our top recommendation. They absorb into the concrete to create a water-repelling barrier that resists moisture, freeze-thaw damage, and salt. Because they are breathable, they won’t trap moisture.

- Epoxy Sealers: These create a hard, durable film that’s great for chemical and abrasion resistance. However, they are non-breathable and can trap moisture if used on exterior foundation walls, leading to failure.

- Cementitious Coatings: These are cement-based products applied to the surface. They can stop water but are rigid and may crack with foundation movement.

- Acrylic Sealers: Primarily decorative, these film-formers offer minimal waterproofing and have a short lifespan (1-5 years), requiring frequent reapplication.

For a truly comprehensive understanding of concrete protection, we recommend our Concrete Foundation Waterproofing Ultimate Guide.

Sealers for Wood or Metal Skirting

Skirting requires different protection than the concrete foundation.

- For Wood Skirting: Use an oil-based wood sealer. It penetrates deeply to repel water, prevent splitting, and provide UV protection. Reapply every 3-5 years to maintain effectiveness.

- For Metal Skirting: Use an elastomeric or rubberized coating. These flexible coatings form a waterproof barrier that stretches without cracking and prevents rust. For best results, prime the metal with a rust-inhibiting primer before applying the topcoat.

Your Step-by-Step Guide to Flawless Foundation Sealing

Properly sealing your mobile home foundation is a manageable project that offers huge returns. While simple surface sealing can be a DIY job, always consult a professional for extensive cracking or water intrusion. At Basement Waterproofing Scientists, we use specialized equipment to find and permanently fix leaks.

Safety is paramount. Always wear safety equipment like gloves, eye protection, and a respirator. Tools needed may include wire brushes, a power washer, rollers, and a low-pressure sprayer.

Pre-Application Prep: The Foundation of Success

A great finish depends entirely on proper prep. Do not skip these steps:

- Clean the Surface: Thoroughly remove all dirt, dust, grease, and loose debris using a wire brush and scraper.

- Remove Old Coatings: Scrape or strip any old, failing paint or sealant. The new sealer needs a stable surface to bond to.

- Power Wash: Use a power washer to blast away embedded grime and mildew for a clean, porous surface.

- Repair Cracks: Before sealing, fill any cracks larger than a hairline with a suitable cement mortar or a specialized sealant. Our guide on Sealing Small Cracks in Foundation can help.

- Ensure Dryness: The surface must be completely dry before applying most sealers. Moisture prevents proper adhesion. (Note: Some penetrating sealers are applied to a damp surface; always read product instructions).

Application Methods and Best Practices

With the prep work done, it’s time to apply the sealer.

- Application Method: Use a brush for corners and details. A roller is efficient for large, flat surfaces. A low-pressure sprayer is fastest for large areas, but always wear a respirator when spraying.

- Achieve Correct Thickness: Follow the product’s specified coverage rate (e.g., square feet per gallon). Applying the sealer too thin offers poor protection, while too thick a coat can cause peeling. Often, two thin coats are better than one thick coat.

- Respect Curing Time: Allow the sealer to fully dry and cure as specified by the manufacturer. Rushing this step can lead to premature failure. Curing can take anywhere from a few hours to several days.

For more detailed guidance on exterior applications, check out our Exterior Foundation Sealing guide.

Choosing the Best Sealer for a Mobile Home Foundation

Selecting the best sealer for mobile home foundation protection is a strategic choice based on your home’s specific needs. It’s about balancing initial cost considerations with long-term value. A more expensive penetrating sealer with a 10+ year lifespan is often a better investment than a cheap acrylic needing reapplication every two years.

Using the wrong sealer is a significant risk. An incompatible product can trap moisture, peel, or fail to waterproof, wasting your time and money and potentially causing more damage.

How Climate Impacts the Choice for the Best Sealer for a Mobile Home Foundation

Your local climate in Pennsylvania, New Jersey, or Delaware is a critical factor in your decision.

- High Humidity Regions: A breathable sealer (like a penetrating siloxane) is essential to allow water vapor to escape, preventing trapped moisture.

- Freeze-Thaw Climates: To prevent cracking from expanding ice, you need a sealer that stops water absorption. Penetrating sealers excel at this.

- UV Exposure: For any above-grade skirting, choose a sealer with UV inhibitors to prevent the sun from breaking it down.

- Salt Air Corrosion: If you’re near the NJ or DE coast, select a sealer that offers chloride and salt resistance to protect concrete and metal.

Our Best Foundation Sealant Guide digs deeper into these environmental considerations.

Maintenance and Longevity: What to Expect from the Best Sealer for a Mobile Home Foundation

Understanding a sealer’s lifespan and maintenance needs is key to long-term success. As noted in our table, lifespans range from 1-5 years for acrylics to 10+ years for high-quality penetrating sealers. Some silicate products can even last the lifetime of the concrete.

Regardless of the type, establish a regular inspection schedule. At least once a year, check your foundation for signs of wear, peeling, new cracks, or areas where water no longer beads. When it’s time for reapplication, the process typically involves a thorough cleaning before applying a fresh coat. Always follow the manufacturer’s specific guidelines to ensure continued protection.

Frequently Asked Questions about Mobile Home Foundation Sealers

How do I know if my foundation already has a sealer?

There are two simple tests. First, the water bead test: sprinkle some water on the foundation. If it beads up on the surface, a sealer is present and working. If it soaks in and darkens the material, it is unsealed or the sealer has failed. Second, a visual inspection: look for a slight sheen on the surface or signs of peeling or flaking, which indicate a failing film-forming sealer.

Can I use a roof coating product on my foundation?

It’s generally not recommended, though some products are rated for both. The formulations are different. Roof coatings are designed for UV resistance and flexibility against weather from above. Foundation sealers are built to withstand hydrostatic pressure and constant moisture from the ground. Using the wrong product can lead to poor adhesion and premature failure. When in doubt, always use a product specifically made for foundations. For more on specialized coatings, see our Foundation Tar Sealer Complete Guide.

What are the risks of using the wrong type of sealer?

Using the wrong sealer can be worse than using no sealer at all. The primary risks include:

- Trapped Moisture: Non-breathable sealers trap water inside the foundation, promoting mold and material decay.

- Peeling and Blistering: The pressure from trapped moisture causes film-forming sealers to bubble and peel off.

- Ineffective Waterproofing: The product simply fails to protect your foundation from water, pests, and freeze-thaw damage.

- Wasted Money and Time: You’ll have to strip the failed product and start over, doubling your cost and effort.

- Accelerated Damage: By trapping moisture, an incorrect sealer can worsen rot and rust in adjacent structural components.

Protect Your Investment with Expert Foundation Care

Choosing the best sealer for your mobile home foundation is a critical investment in your home’s health, safety, and longevity. The right product—matched to your foundation material and local climate in PA, NJ, or DE—provides lasting protection against moisture, pests, and structural damage, saving you from expensive future repairs.

While some sealing can be a DIY project, complex issues like persistent water intrusion, significant cracking, or structural concerns demand professional expertise. At Basement Waterproofing Scientists, we bring 30 years of specialized experience to every job. We use advanced equipment to accurately identify leak sources, allowing us to provide guaranteed, permanent solutions for less. The average cost for professional waterproofing is between $4K and $8K—a worthwhile investment for a permanently dry and protected home.

Don’t leave your most valuable asset vulnerable. For a professional assessment of your property’s needs, we invite you to contact our foundation experts for a comprehensive evaluation. Let us help you protect your investment for years to come.