Why How to Epoxy Paint a Basement Floor Transforms Your Space

How to epoxy paint a basement floor involves five critical steps that turn dull concrete into a durable, waterproof surface:

- Prepare the concrete – Clean, repair cracks, and profile the surface by grinding or etching.

- Mix the epoxy – Combine Part A (resin) and Part B (hardener) per the manufacturer’s ratio.

- Apply the base coat – Pour, spread with a squeegee, and back-roll with a 3/8″ nap roller.

- Add decorative elements (optional) – Broadcast color flakes onto the wet epoxy.

- Apply a topcoat – Seal with a polyaspartic or polyurethane topcoat for durability and UV resistance.

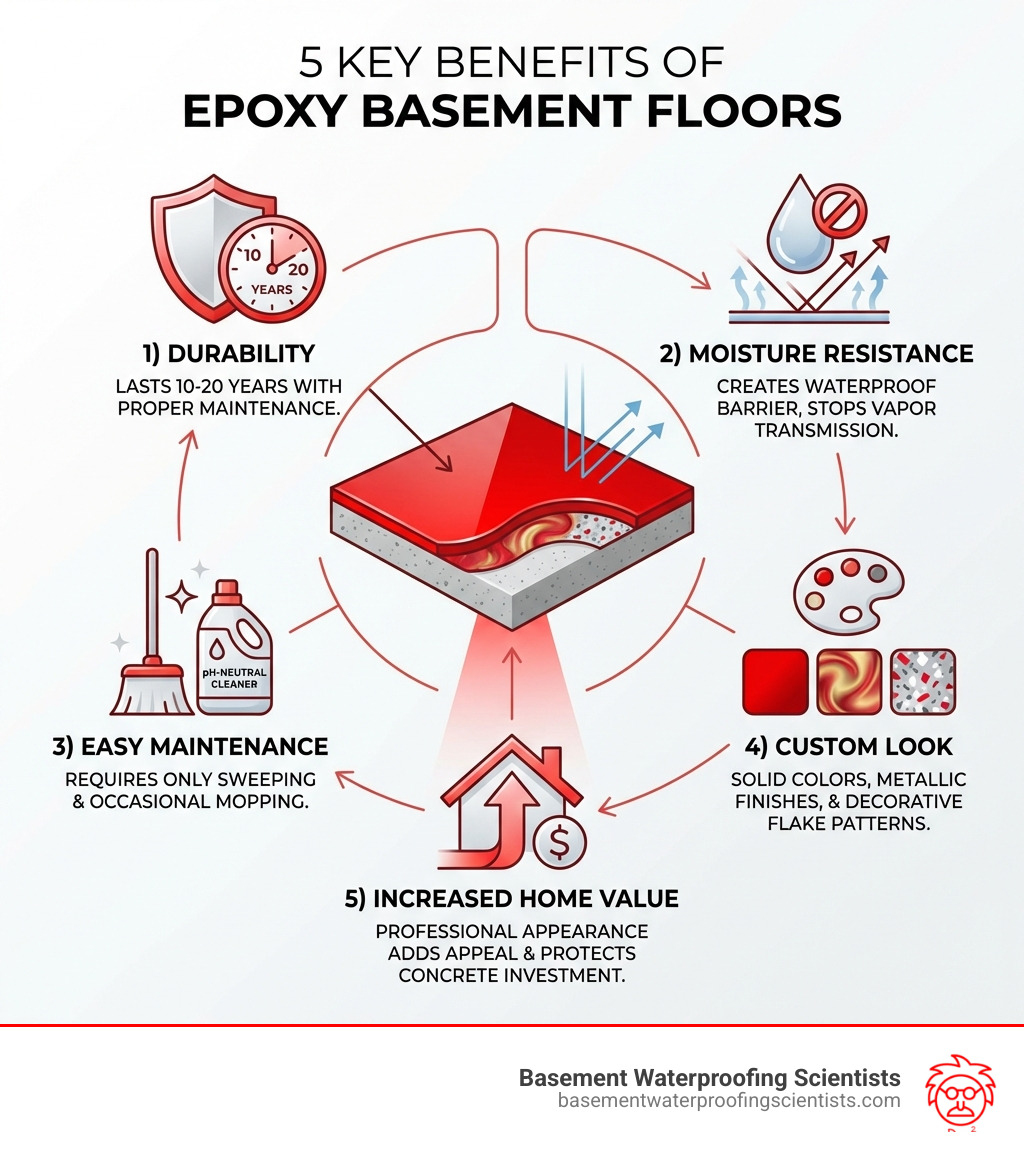

Unfinished concrete floors are porous, dusty, and prone to moisture damage. Epoxy floor coatings solve these problems by creating a seamless, waterproof barrier that’s both functional and beautiful. The benefits are compelling: epoxy lasts 10-20 years, resists moisture, is easy to clean, offers great aesthetic flexibility, and is a cost-effective DIY project.

Success hinges on proper preparation, which accounts for 80% of the job. Skipping steps like cleaning, repairing, and profiling the concrete will lead to peeling and failure. Temperature and timing are also critical; apply epoxy between 50°F and 90°F and be mindful of its limited working time (typically 45-60 minutes). The floor can handle light traffic in 24 hours but needs up to 7 days to fully cure.

I’m Darin Garvey, and with over 30+ years in basement waterproofing, I’ve seen how proper how to epoxy paint a basement floor techniques can achieve a showroom-quality finish. This guide provides the actionable steps you need.

Terms related to how to epoxy paint a basement floor:

Understanding Epoxy and Why It’s Perfect for Basements

Epoxy isn’t just paint; it’s a two-part resin system that, when mixed, creates a chemical bond with concrete to form an incredibly tough, durable coating. This makes it far superior to standard paint for basements, which are often damp. Epoxy acts as a waterproof moisture barrier, protecting the concrete and helping to prevent mold growth.

If you want to dig a little deeper into how epoxy resins work at a chemical level, you can read more in this overview of epoxy.

Key benefits of choosing epoxy for your basement include:

- Exceptional Durability: A properly applied epoxy floor can last 10-20 years, far outperforming the 3-5 year lifespan of typical concrete paint.

- Superior Moisture Resistance: Epoxy creates a non-porous, waterproof seal that helps stop moisture vapor transmission through the concrete.

- Easy Maintenance: The seamless surface is easy to clean. Spills wipe up effortlessly, and routine care only requires sweeping and occasional mopping.

- Cost-Effectiveness: With DIY kits starting around $500, epoxy is a budget-friendly solution with long-term value due to its durability and low maintenance.

Types of Epoxy Coatings

For basements, 100% solids epoxy is the gold standard. It contains no solvents, releases virtually no volatile organic compounds (VOCs), and offers the highest durability and chemical resistance. We highly recommend it for its longevity and minimal fumes. Other types, like water-based or solvent-based epoxies, are generally less durable and may have higher VOCs, making them less suitable for indoor residential use. Always aim for a high-solids or 100% solids product for maximum protection.

Designing Your Floor: Colors, Patterns, and Flakes

One of the most exciting aspects of how to epoxy paint a basement floor is the aesthetic change.

- Colors and Finishes: Lighter colors and gloss finishes can make a basement feel brighter and more spacious by reflecting light.

- Decorative Flakes: These small vinyl chips are broadcast onto the wet epoxy to add texture, hide minor imperfections, and create a granite-like appearance.

- Metallic Epoxy: For a unique, high-end look, metallic pigments can be added to create stunning, three-dimensional effects that mimic marble or flowing water.

Your basement floor can be as simple or as decorative as you desire. You can explore more about your options by visiting our Epoxy Floor Paint Colors page.

Phase 1: Critical Preparation for a Flawless Finish

Proper surface preparation accounts for 80% of the project’s success. Skipping steps here is the number one reason for coating failure, leading to peeling and bubbling. The epoxy needs a clean, dry, and porous surface to create a lasting bond.

[LIST] of Essential Materials and Tools

- Epoxy Coating Kit (Part A Resin, Part B Hardener)

- Two-part resin-based concrete patch/filler

- Heavy-duty degreaser or TSP cleaner

- Concrete Etch (e.g., DRYLOK Etch)

- Diamond Grinder or Concrete Sander (highly recommended)

- Wet/Dry Shop Vacuum

- Notched Squeegee

- 3/8″ Nap Rollers, Brushes, and Extension Pole

- Spiked Shoes

- Mixing Buckets (with liners)

- Drill with Mixing Paddle

- Protective Gear: Chemical-resistant gloves, safety glasses, respirator mask

- Painter’s Tape and Plastic Sheeting

How to Prepare Your Basement Floor for Epoxy Paint

Follow these steps carefully for a professional, long-lasting finish.

- Clear and Clean: Remove everything from the floor. Sweep and vacuum all loose dirt. Then, scrub the entire floor with a heavy-duty degreaser or TSP solution to remove oils and contaminants. Rinse thoroughly and use a squeegee or wet vac to remove all water.

- Test for Moisture: Tape a 2×2 ft plastic sheet to the floor. After 24 hours, check for condensation. If moisture is present, you must address the underlying issue before applying epoxy, as it will cause the coating to fail. For persistent issues, consult a professional. Learn more at our Waterproofing Basement Floor page.

- Repair Cracks: Inspect the floor for cracks or holes. Widen hairline cracks with a diamond blade, vacuum the debris, and fill all imperfections with a two-part resin-based patching compound. Grind the patches flush once cured.

- Profile the Surface (Grinding or Etching): This is the most critical step for adhesion. The goal is a texture similar to medium-grit sandpaper.

- Diamond Grinding (Preferred Method): Grinding is the best way to prepare concrete. It effectively removes old coatings, sealers, and creates the ideal profile. If water beads on your floor, a sealer is present and must be ground off.

- Acid Etching: For bare, unsealed concrete, you can use an acid etch solution. Apply it to a damp floor, scrub, and let it sit for 15 minutes. Rinse thoroughly multiple times to neutralize the acid, as any residue will prevent the epoxy from bonding.

- Final Dry and Taping: Allow the floor to dry completely for at least 24 hours, using fans or a dehumidifier to speed up the process. Once dry, use painter’s tape to mask off walls and any other areas you don’t want coated.

This meticulous preparation ensures the epoxy bonds correctly. For more in-depth guidance, check out our Prepping Basement Floor for Epoxy guide.

Phase 2: How to Epoxy Paint a Basement Floor Step-by-Step

With our meticulous preparation complete, we’re ready for the exciting part: applying the epoxy! Epoxy has a limited “working time” once mixed, so we need to be organized and efficient. The temperature and humidity in your basement will significantly affect this working time and the curing process. Always aim for an ambient temperature between 50°F and 90°F.

Mixing and Applying the Epoxy Base Coat

This is where the change truly begins. Follow these steps carefully for a smooth application:

- Mix the Epoxy: This is a critical step. Following your kit’s ratio (often 1:1 or 2:1), pour Part B into Part A. Using a drill with a mixing paddle, mix vigorously for 3-5 minutes, scraping the sides and bottom of the bucket to ensure thorough blending. Once mixed, the clock starts ticking! Pour the epoxy onto the floor immediately to extend its working time, as a large mass in the bucket will cure faster.

- Cut In and Apply: Use a 3-inch paintbrush to cut in along the perimeter. Working in small 4×4 foot sections from the corner farthest from your exit, pour a line of epoxy onto the concrete. Use a notched squeegee to spread it evenly.

- Back-Roll for a Smooth Finish: Immediately after squeegeeing, use a 3/8″ nap roller to gently back-roll the epoxy. This removes squeegee lines and creates a uniform coat. Wear spiked shoes to walk on the wet epoxy. Always maintain a wet edge by rolling into the previously applied section to avoid lap lines.

For a visually guided experience, we also offer detailed insights on our Applying Epoxy Paint to Concrete Floor page.

Applying Decorative Flakes and a Top Coat

Now for the fun part that truly personalizes your project.

- Broadcasting Decorative Flakes (Optional): If you’re using decorative flakes, they must be applied immediately after you’ve coated a section with the base epoxy while it’s still wet. Toss them upward and outward, allowing them to fall gently onto the epoxy.

- Scraping Excess Flakes: After 12-24 hours, use a flat floor scraper to gently remove any loose or vertical flakes. Vacuum up all the scraped flakes.

- Applying a Top Coat (Highly Recommended): A clear topcoat improves durability and UV resistance. Polyaspartic coatings are an excellent choice. Mix and apply the topcoat using a fresh roller or squeegee, working in sections similar to the base coat. Consider adding a non-slip additive for safety.

You can explore various options for your basement’s surface protection on our Basement Floor Coatings and Epoxy Floor Coatings pages.

Phase 3: Curing, Maintenance, and Common Mistakes

We’ve done the hard work, and your basement floor is looking fantastic! But our job isn’t quite finished. The curing process is crucial for the epoxy to achieve its full strength and durability, and proper maintenance will ensure its longevity. This phase also helps us understand how epoxy contributes to basement waterproofing by sealing the concrete.

[TABLE] comparing Epoxy Drying and Curing Times

Different types of traffic require different curing times. Patience is key here, as rushing this stage can compromise the integrity of your new floor.

| Type of Traffic/Activity | Recommended Curing Time |

|---|---|

| Light Foot Traffic | 24 hours |

| Heavy Foot Traffic | 72 hours |

| Furniture Placement | 72 hours |

| Vehicle Traffic | 7 days |

| Cleaning with Detergent | 30 days |

Note: These are general guidelines. Always refer to your specific epoxy product’s manufacturer instructions, as times can vary based on temperature, humidity, and product formulation.

Long-Term Care and Maintenance

One of the great benefits of an epoxy basement floor is its low maintenance. With a little care, your floor will continue to look great for years to come, potentially lasting 10-20 years!

- Regular Cleaning: Sweep or vacuum your floor regularly to remove dirt and debris. This prevents abrasive particles from scratching the surface.

- Cleaning Spills: Wipe up spills immediately. For routine cleaning, mop the floor with warm water and a pH-neutral cleaner. Avoid harsh chemicals or abrasive cleaners.

- Protect High-Traffic Areas: Place mats at entryways and under heavy furniture. Avoid dragging heavy objects across the floor, which can cause scratches.

How to Avoid Common Mistakes When You Epoxy Paint a Basement Floor

Even with the best intentions, mistakes can happen. By being aware of them, you can avoid them:

- Poor Surface Preparation: This is the #1 cause of failure. Inadequate cleaning, degreasing, or profiling will lead to adhesion failure, causing the epoxy to peel or bubble.

- Ignoring Moisture Issues: Applying epoxy over a damp concrete slab is a recipe for disaster. Always perform a moisture test. If you have persistent moisture, see our Epoxy Basement Floor Waterproofing page for solutions.

- Improper Mixing: If Part A and Part B aren’t mixed thoroughly and according to instructions, the epoxy may not cure properly, remaining tacky or soft in spots.

- Wrong Temperature or Humidity: Applying epoxy outside the recommended 50°F – 90°F range can affect cure times and adhesion.

- Rushing Cure Times: Patience is vital. Ignoring the recommended curing times for foot traffic and furniture can damage the still-vulnerable epoxy.

Frequently Asked Questions about Epoxy Basement Floors

We often hear similar questions from homeowners starting on their epoxy basement floor journey. Here are some of the most common ones, answered with our expert insights.

Can I apply epoxy over an existing coating or painted floor?

This is not recommended. For optimal adhesion, you must remove any existing paint, sealers, or coatings.

- Best Method: Grinding the floor with a diamond grinder is the most effective way to remove old coatings. Do not acid etch over painted surfaces.

- Testing for Sealers: If you’re unsure if a sealer is present, pour a small amount of water on the surface. If it beads up, a sealer is present and must be mechanically removed.

- Recoating Epoxy: A well-bonded epoxy floor can be recoated, but it requires thorough cleaning and surface profiling (sanding or grinding) to create a mechanical bond.

How does epoxy flooring compare to other basement options?

Epoxy offers a unique blend of benefits compared to other popular basement flooring choices.

- Cost: DIY epoxy kits can start around $500, making them a very budget-friendly option compared to professional installations of other materials.

- Durability vs. Tile/Carpet: Epoxy provides an industrial-grade strength that is more resilient and impact-resistant than tile, carpet, or standard vinyl.

- Maintenance vs. Carpet/Hardwood: The non-porous, seamless surface is exceptionally easy to clean and more sanitary than carpet or tile with grout lines.

- Waterproofing vs. Other Options: This is where epoxy truly stands out for basements. It creates a waterproof barrier, actively protecting your concrete from moisture. Unlike laminate or carpet, which can be ruined by water, epoxy forms a protective seal.

What are the most important safety precautions for working with epoxy?

Working with epoxy involves chemicals, so safety is paramount.

- Ventilation: Provide ample ventilation throughout the process by opening windows and using fans to circulate air.

- Respirator Mask: Wear a NIOSH-approved respirator mask, especially when grinding the concrete or working with solvent-based epoxies.

- Safety Glasses: Always wear safety glasses or goggles to protect your eyes from splashes and dust.

- Chemical-Resistant Gloves: Wear chemical-resistant gloves to prevent skin contact with the epoxy components.

- Proper Disposal: Allow any unused epoxy to harden completely before discarding it according to local regulations. Never pour liquid epoxy down drains.

Conclusion

Changing your basement floor with epoxy is a rewarding DIY project that yields a durable, beautiful, and highly functional space. By following our detailed guide on how to epoxy paint a basement floor, you’re investing in your home’s longevity and aesthetic appeal. The key to success lies in meticulous preparation, precise application, and diligent curing.

A properly epoxied basement floor offers unparalleled durability, superior moisture resistance, and effortless maintenance. However, it’s crucial to remember that while epoxy provides an excellent moisture barrier, it’s a surface solution. If you’re experiencing persistent or significant water intrusion, such as leaks through foundation cracks or hydrostatic pressure issues, a coating alone won’t solve the problem.

For underlying moisture issues that paint can’t solve, the experts at Basement Waterproofing Scientists can identify and permanently fix the source of the leak. We specialize in basement waterproofing and structural repairs in Pennsylvania, New Jersey, and Delaware, offering customized solutions to ensure permanently dry basements. With our 30 years of experience, we use specialized equipment to identify leak sources and provide expert inspections, backed by a lifetime guarantee.

Ready to explore all your options for a dry, beautiful basement? Learn more about our professional Basement Floor Coatings.