Why Sealing Block Basement Walls is Critical for Your Home

Sealing block basement walls is essential for preventing water damage, protecting your home’s foundation, and creating a healthy living space. Block walls are significantly more porous than poured concrete, making them vulnerable to water intrusion through hollow cores, mortar joints, and the blocks themselves.

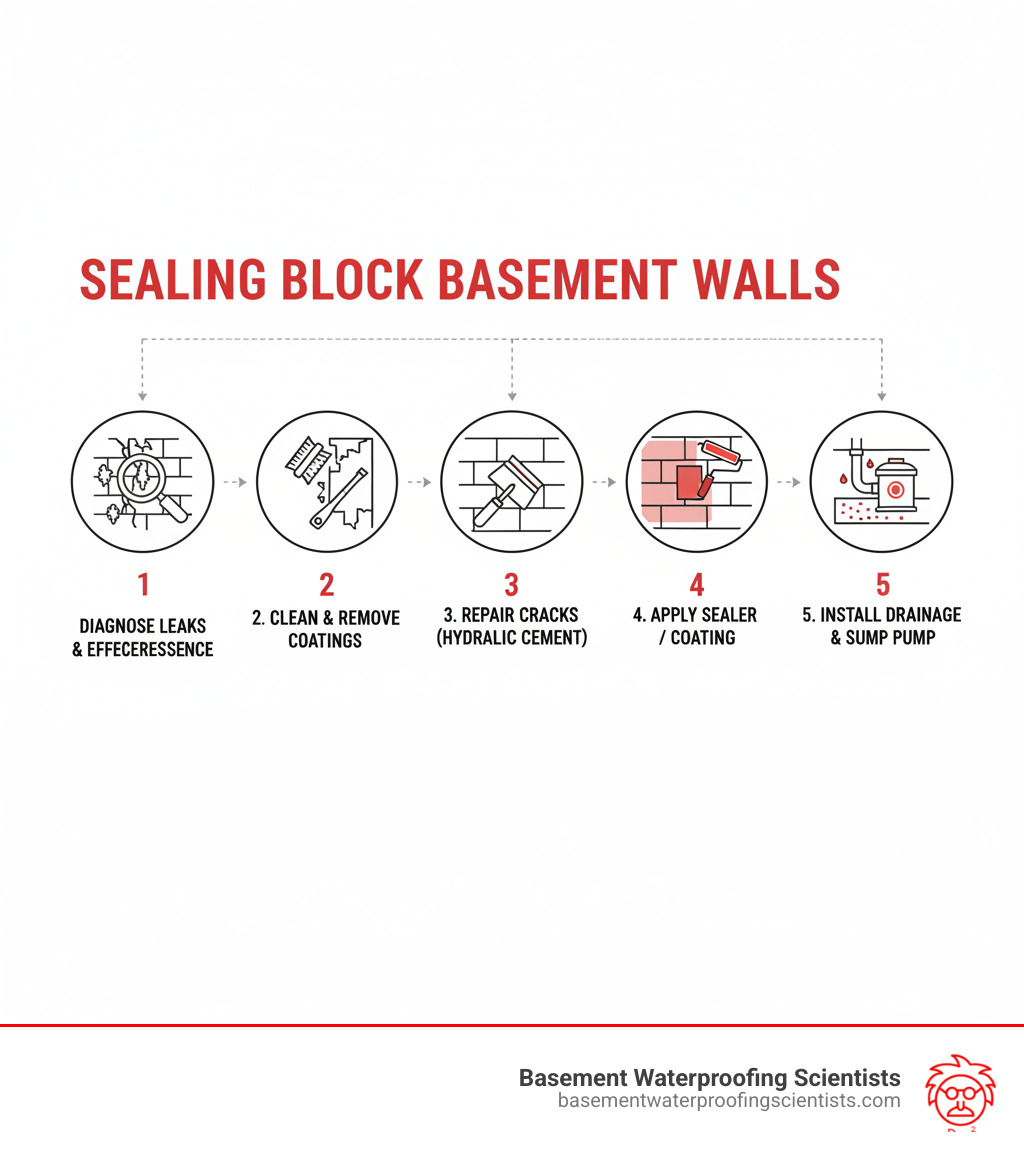

Quick Answer: Steps to Seal Block Basement Walls

- Diagnose the source of leaks and drainage issues.

- Prepare the surface by cleaning walls and repairing cracks.

- Choose your method, such as interior coatings or exterior waterproofing.

- Apply the sealer according to manufacturer instructions.

- Manage water with drainage systems and proper gutter maintenance.

Your basement is your home’s foundation. Water seepage can lead to structural damage, mold, and costly repairs, with average waterproofing costs ranging from $4K to $8K. Concrete blocks have hollow cores that can fill with water, creating pressure that pushes moisture through the walls. Mortar joints also crack over time, providing another entry point for water.

With the right approach, you can transform a damp basement into a dry, usable space. This guide walks you through identifying leaks, choosing products, and proper application. With over 30 years of experience in basement waterproofing, I’ll share proven techniques for achieving a permanently dry basement through expert leak detection and customized sealing block basement walls solutions.

Step 1: Diagnosing the Problem and Understanding the Causes

Before you can fix a leak, you must understand its cause. Effective sealing block basement walls starts with identifying why water is getting in, so you can solve the real problem instead of just treating symptoms.

Why Your Block Basement Walls Are Leaking

Water intrusion is often a combination of factors. Here are the main culprits:

- Hydrostatic pressure: When soil around your foundation becomes saturated, it creates immense pressure against the walls. This forces water through cracks, mortar joints, and the porous blocks. The hollow cores in block walls can fill with water, increasing internal pressure and pushing moisture through.

- Poor exterior drainage: If your yard slopes toward your house, it directs rainwater straight to your foundation. This water saturates the soil, leading to hydrostatic pressure.

- Clogged gutters and downspouts: Overflowing gutters dump water directly next to your foundation. Downspouts that terminate at the foundation wall concentrate water flow, saturating the soil and causing leaks.

- Saturated soil: Concrete blocks act like sponges, wicking moisture from wet soil directly into your basement through microscopic capillaries.

- Foundation settlement cracks: As a house settles, cracks can form in block walls and mortar joints, creating express lanes for water intrusion.

The University of Minnesota Extension offers more insights on the common causes of basement moisture and potential solutions.

Telltale Signs of Water Intrusion

Your basement walls will show warning signs that it’s time for sealing block basement walls.

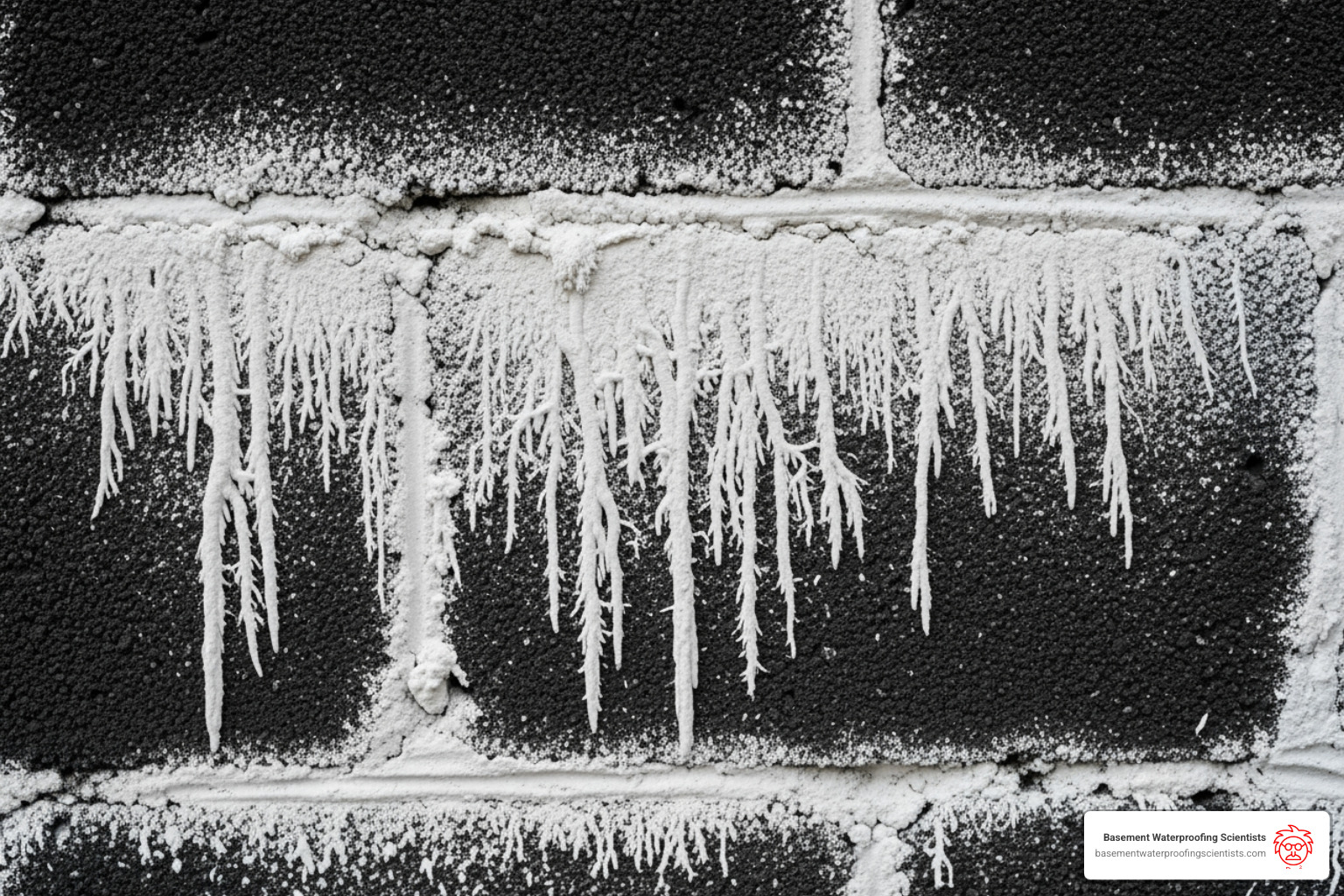

- Efflorescence: This white, powdery substance is mineral salts left behind when water evaporates from the concrete. It’s a sure sign that water is moving through your walls.

- Musty odor: This smell comes from mold and mildew growing in damp conditions and is often one of the earliest signs of a moisture problem.

- Visible mold or mildew: Black, green, or white fuzzy patches on walls or floors indicate high moisture levels and a potential health concern.

- Damp spots or water stains: Discolorations on the walls show exactly where water is entering, especially after rain.

- Peeling paint or wallpaper: Moisture pushing from behind the wall causes coatings to bubble, flake, or detach.

- Puddles on the floor: Water at the wall-floor joint is a classic symptom of hydrostatic pressure forcing water through the weakest point in your foundation.

Catching these signs early makes repairs easier and less expensive. At Basement Waterproofing Scientists, we use specialized equipment to pinpoint leaks at their source, allowing for targeted and cost-effective repairs.

Step 2: Essential Preparation Before Sealing Block Basement Walls

The difference between a temporary fix and a lifetime solution is preparation. A waterproofing product is only as good as the surface it’s applied to. Rushing this step will lead to failure.

Cleaning and Clearing the Surface

Your walls must be completely clean before applying any sealer. Start by clearing items away from the walls to give yourself room to work. Use a stiff wire brush to remove all loose dirt, dust, and crumbling mortar.

For stubborn grime, pressure washing is effective, but you must allow the walls to dry completely for several days afterward.

Crucially, all old paint and failed coatings must be removed. Waterproofing products need to bond directly with the bare masonry. Paint acts as a barrier that prevents this bond. Scrape, wire brush, or use chemical removers to get down to the clean, bare concrete block. This step is non-negotiable for a lasting seal.

Repairing Cracks and Voids

Before sealing block basement walls, every crack and hole must be addressed to prevent future leaks.

For active leaks or larger cracks (up to 1/4 inch), use hydraulic cement. This material sets and hardens even in water, expanding as it cures to create a watertight seal. Apply it with a putty knife and hold it in place for a few minutes as it sets.

For larger cracks, a professional tip is to widen the crack into an inverted ‘V’ shape with a chisel. This allows the patching material to lock into the crack more securely. For smaller, non-leaking cracks, a high-quality masonry caulk is sufficient.

Always allow patching materials to cure fully according to the manufacturer’s instructions before proceeding.

Removing Efflorescence and Ensuring Walls are Dry

Efflorescence—the white, powdery substance on your walls—must be completely removed. For light deposits, use a stiff wire brush. For stubborn efflorescence, use an acid-based cleaner, such as a muriatic acid solution. Always wear protective gloves, goggles, and a respirator when working with acids, and rinse the walls thoroughly afterward.

Most importantly, the walls must be completely dry before sealing. Applying sealants to damp walls is the number one cause of waterproofing failure. To aid drying, use fans and a dehumidifier to circulate air and remove moisture. If you suspect water is trapped in the block cores, you may need to drill small weep holes at the bottom of the wall to allow it to drain. Be patient; this drying process can take several days or even weeks. A bone-dry wall is essential for success.

Step 3: Choosing Your Waterproofing Method and Products

Choosing the right strategy for sealing block basement walls is like selecting the right tool for a job. The method and product must match the problem.

Interior vs. Exterior: Which Approach is Right for You?

This is a critical decision based on your situation, budget, and the severity of the water problem.

- Exterior Waterproofing (Positive-Side): This method stops water before it touches your foundation. It’s the most effective approach as it addresses the root cause, but it is also expensive and disruptive, requiring excavation around your home. This is a job for professionals.

- Interior Waterproofing (Negative-Side): This method manages water after it has entered the wall structure. It’s less expensive and non-disruptive, making it suitable for DIY projects. It works well for minor dampness but means water is still present within the blocks, which can cause issues over time.

Choose interior waterproofing for minor dampness, budget constraints, or when excavation is impossible. Opt for exterior waterproofing for significant water intrusion, high hydrostatic pressure, or to best protect your foundation’s structural integrity.

A Guide to Waterproofing Products

Concrete blocks are highly permeable, so choosing the right product is vital for sealing block basement walls. According to the ASHRAE Handbook, their porosity is much higher than poured concrete.

- Waterproofing Paints: Acrylic or latex-based coatings suitable for only very mild dampness. They will not hold back significant water pressure.

- Cementitious Coatings: Cement-based products that create a hard, durable, and watertight barrier. They bond well with masonry and can withstand hydrostatic pressure.

- Elastomeric Liquid Membranes: Flexible, rubber-like coatings that can stretch to bridge minor cracks. They form a seamless waterproof film on the surface.

- Penetrating Sealers: Silicate or silane/siloxane products that soak into the block and chemically react to form an internal water-repellent barrier. The wall can still “breathe,” allowing vapor to escape.

- Crack Injection Materials: Polyurethane or epoxy resins used to seal individual cracks. Polyurethane is flexible, while epoxy creates a rigid, structural bond.

The Importance of Water Management Systems

Even the best sealant needs a water management system to be effective.

- Interior Drain System (French Drain): Installed along the basement perimeter to collect water that seeps through and directs it to a sump pump.

- Sump Pump: Sits in a basin and automatically pumps collected water out of the basement and away from the foundation.

- Vapor Barriers and Dimple Boards: Barriers block moisture, while dimple boards direct water from the wall-floor joint into the drain system.

- Weep Holes: Small holes drilled in the bottom course of hollow block walls to allow trapped water to drain into the interior system. This is essential for block foundations.

Step 4: The Application Process for Sealing Block Basement Walls

Proper application is where your preparation pays off. When sealing block basement walls, always follow the manufacturer’s instructions precisely for the best results.

Applying Coatings and Membranes

For waterproofing paints, cementitious coatings, or elastomeric membranes, follow these steps:

- Read the Label: Each product has specific mixing, temperature, and drying time requirements. Do not ignore them.

- Use the Right Tools: A thick-nap roller (3/4-inch) is best for working the product into the porous block surface. Use a brush for corners and edges.

- Apply Generously: Don’t try to stretch the product. Apply a thick, even coat to ensure complete coverage. Thin coats will fail under pressure.

- Apply Multiple Coats: Plan on at least two coats. Allow the first coat to dry completely according to the label before applying the second. Rushing this step will cause the second coat to fail.

- Back-Brush: After rolling, use a brush to work the coating deeper into the pores and mortar joints for a stronger bond.

Using Penetrating Sealers for Sealing Block Basement Walls

Penetrating sealers work differently from surface coatings.

These products, containing chemicals like silicates or silanes, soak into the concrete and react to form a permanent, internal waterproof barrier. The science behind silane sealers involves tiny molecules creating an invisible water-repellent lattice inside the block, allowing the wall to breathe. Crystalline products work similarly, growing needle-like crystals in the pores to block water.

Application is typically done with a low-pressure garden sprayer for even coverage. Some products require the surface to remain wet for a period to ensure maximum penetration. The curing process is a chemical change that can take days or weeks to reach full effectiveness.

Tips for a Successful Application

- Temperature: Apply sealers within the manufacturer’s recommended temperature range (usually 50°F to 90°F). Applying in extreme cold or heat can cause the product to fail.

- Ventilation: Ensure good airflow by opening windows and using fans. Wear a respirator for products with strong fumes.

- Safety Gear: Always use chemical-resistant gloves, eye protection, and a respirator.

- Time: Do not rush. Plan for multiple days to account for application and proper drying times between coats.

DIY Project or Professional Job: Making the Right Call

Now you must decide: tackle sealing block basement walls yourself, or call in the experts? The answer depends on the severity of the problem.

When a DIY Approach Makes Sense

A DIY approach can be effective and save money for minor issues:

- Minor Dampness & Efflorescence: If you only see powdery residue or have a musty smell without active leaks, cleaning the walls and applying an interior sealer may be sufficient.

- Small, Non-Structural Cracks: Hairline cracks that aren’t leaking can be patched with hydraulic cement or masonry caulk.

- Applying Waterproof Paint: For very mild condensation issues, waterproof paint can serve as a first line of defense, but it won’t stop active leaks.

- Limited Budget: If the problem is minor, starting with DIY fixes like improving drainage and applying a sealer is a practical first step.

Signs It’s Time to Call a Professional

Some problems are not DIY projects and require expert attention to avoid wasting money or causing further damage.

- Large or Structural Cracks: Horizontal, stair-step, or wide cracks signal potential foundation movement and require professional assessment.

- Bowing or Bulging Walls: This is a sign of extreme hydrostatic pressure or structural failure. Call a professional immediately.

- Significant Water Intrusion: Standing water or active streams entering your basement require a comprehensive solution, like a professional drainage system.

- High Hydrostatic Pressure: If water is being forced through the floor-wall joint, you need a professional to design a system that can manage the pressure.

- Exterior Waterproofing: Excavation and applying exterior membranes should always be left to professionals with the right equipment and expertise.

- Widespread Mold: This indicates a major moisture problem that needs professional remediation for health and safety reasons. For more on this, the EPA offers guidance on remodeling and indoor air quality.

At Basement Waterproofing Scientists, we use specialized equipment to pinpoint leak sources, allowing us to fix the problem correctly for less. The average cost for professional waterproofing is $4K to $8K, but our customized solutions, backed by a lifetime guarantee, ensure your basement stays permanently dry.

Frequently Asked Questions about Sealing Block Walls

Here are straightforward answers to some of the most common questions we hear about sealing block basement walls.

Can I apply a waterproofer over a painted wall?

No. Waterproofing products must bond directly with the porous masonry to be effective. Paint creates a barrier that prevents this bond, leading to product failure under water pressure. For a lasting seal, the surface must be stripped down to the bare block. Skipping this step means your new coating will likely peel off, wasting your time and money.

How long does interior basement waterproofing last?

The lifespan of an interior waterproofing job varies, but a typical treatment lasts about 10 years. Longevity depends heavily on exterior conditions. If you have poor yard grading or clogged gutters constantly directing water to your foundation, the interior seal will be under constant stress and may fail sooner. Proper preparation and managing exterior water are the keys to extending the life of your interior waterproofing.

Should I seal my block walls before applying stucco?

No. Stucco is a cement-based material that needs to bond with a porous surface. Sealing the block first creates a smooth barrier that prevents the stucco from adhering properly. This can cause the stucco to fail and delaminate over time as moisture gets trapped between the sealer and the stucco. An unsealed block wall provides the ideal surface for stucco application.

Conclusion: Ensuring a Permanently Dry Basement

From diagnosis to application, you now have a roadmap to a dry basement. However, sealing your walls is not a one-time fix; long-term maintenance is key to ensuring your basement stays dry.

Long-Term Maintenance for Sealed Walls

To protect your investment, follow these simple maintenance steps:

- Regularly Inspect Walls: Periodically check for new cracks, damp spots, or efflorescence. Early detection saves money.

- Keep Gutters Clean: Clogged gutters are a primary cause of basement water issues. Clean them regularly and ensure downspouts discharge water at least six feet from the foundation.

- Maintain Yard Grade: Ensure the soil around your foundation slopes away from the house to direct water away.

- Test Your Sump Pump: If you have one, test your sump pump annually by pouring a bucket of water into the pit to ensure it’s working.

The Value of an Expert Assessment

Effective sealing block basement walls requires a systematic approach that addresses both interior and exterior factors. At Basement Waterproofing Scientists, our specialized equipment allows us to find the precise source of leaks, enabling us to provide targeted, less expensive repairs. With 30 years of experience serving Pennsylvania, New Jersey, and Delaware, we offer customized solutions with a lifetime guarantee.

Don’t let a damp basement compromise your home. For an accurate diagnosis and a permanent solution, get a professional foundation sealant assessment from us today.