Why Choosing the Right Cinder Block Foundation Sealer Matters

A cinder block foundation sealer is your first line of defense against water intrusion and structural damage. Understanding your options is key to preventing costly moisture problems before they start.

Quick Guide to Cinder Block Foundation Sealers:

- Penetrating Sealers – Work below the surface by chemically bonding with the block (best for preventative protection).

- Film-Forming Coatings – Create a visible barrier on the surface (ideal for bridging small cracks).

- Cementitious Waterproofers – Thick cement-based coatings that resist hydrostatic pressure (best for exterior applications).

The right choice depends on your block’s condition, whether you’re sealing inside or outside, and if you’re dealing with active leaks or preventing future ones.

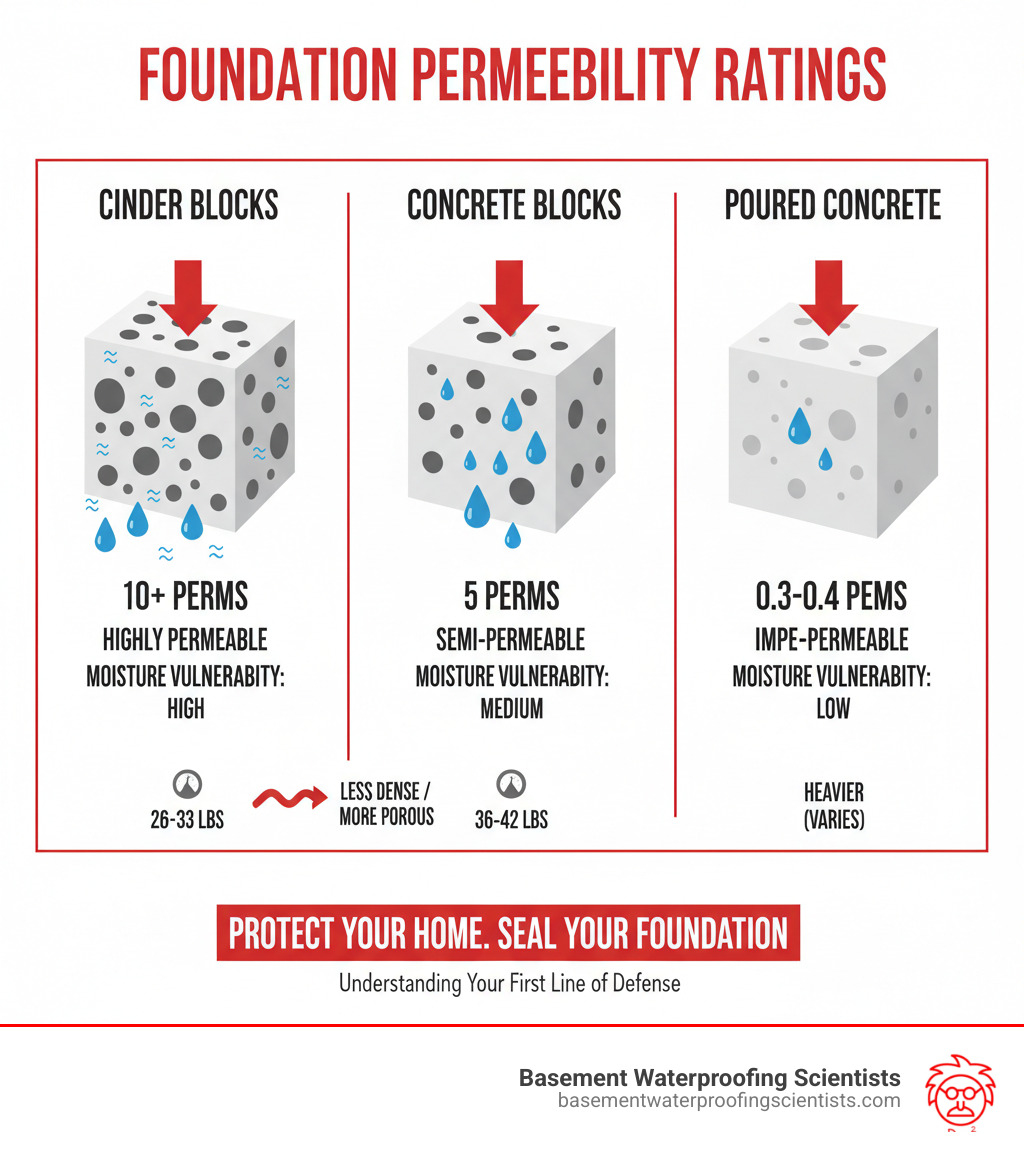

Cinder blocks are highly permeable (over 10 perms), allowing water and vapor to pass through easily. For comparison, poured concrete is nearly impermeable (0.3-0.4 perms), making sealing cinder blocks critical. Their lighter weight (26-33 lbs vs. 36-42 lbs for concrete blocks) indicates higher porosity. Their hollow cores can fill with water, creating a reservoir that seeps into your basement long after a storm.

Ignoring this leads to efflorescence (white powder), mold, and structural damage. Continuous moisture enlarges the block’s pores, worsening leaks and making them harder to seal over time. Sealing your foundation early is far more effective than dealing with active leaks.

I’m Darin Garvey, with 30 years of experience in basement waterproofing in the Philadelphia area. Choosing the right cinder block foundation sealer can prevent thousands in repairs. My team uses advanced leak detection to find the source of water entry, ensuring we recommend the most effective sealing solution for your home.

Why Your Cinder Block Foundation Leaks and Needs Sealing

A damp, musty basement smell is a common complaint from homeowners in areas like Reading and Norristown. Often, the culprit is a cinder block foundation. All concrete materials need protection from water intrusion, but cinder blocks are especially vulnerable. Their composition practically invites water inside, which is why choosing the right cinder block foundation sealer is essential for a dry basement. Our Waterproofing Block Wall Foundation Guide offers a broad overview, but let’s examine why these foundations leak.

Cinder blocks (CMUs) are inherently porous, creating a highway for water. Each block has tiny pathways, and every mortar joint is a potential entry point. Combined with hydrostatic pressure (water in the soil pushing against the wall), soil settlement, and mortar joint degradation, leaks are inevitable. The hollow cores in cinder blocks act like reservoirs, filling with groundwater and slowly seeping into the basement for days or weeks after rain stops. For complete solutions, see our Foundation Repair and Waterproofing page.

Understanding Cinder Blocks vs. Concrete Blocks

Though often used interchangeably, “cinder block” and “concrete block” are different, and this distinction matters for waterproofing.

Traditional cinder blocks used fly ash or bottom ash as aggregate, making them lighter and more porous. A cinder block weighs 26-33 pounds, while a denser heavyweight concrete block is 36-42 pounds. This weight difference reflects density and water resistance.

In terms of permeability ratings, cinder blocks are over 10 perms (highly permeable). Heavyweight concrete blocks are around 5 perms (semi-permeable), while a poured concrete wall is just 0.3-0.4 perms (nearly impermeable). The thin walls of a cinder block offer little resistance to water, making them more like a sieve than a dam.

Common Signs of Water Intrusion

Water intrusion often starts with subtle signs. Catching them early can save you thousands in future repairs.

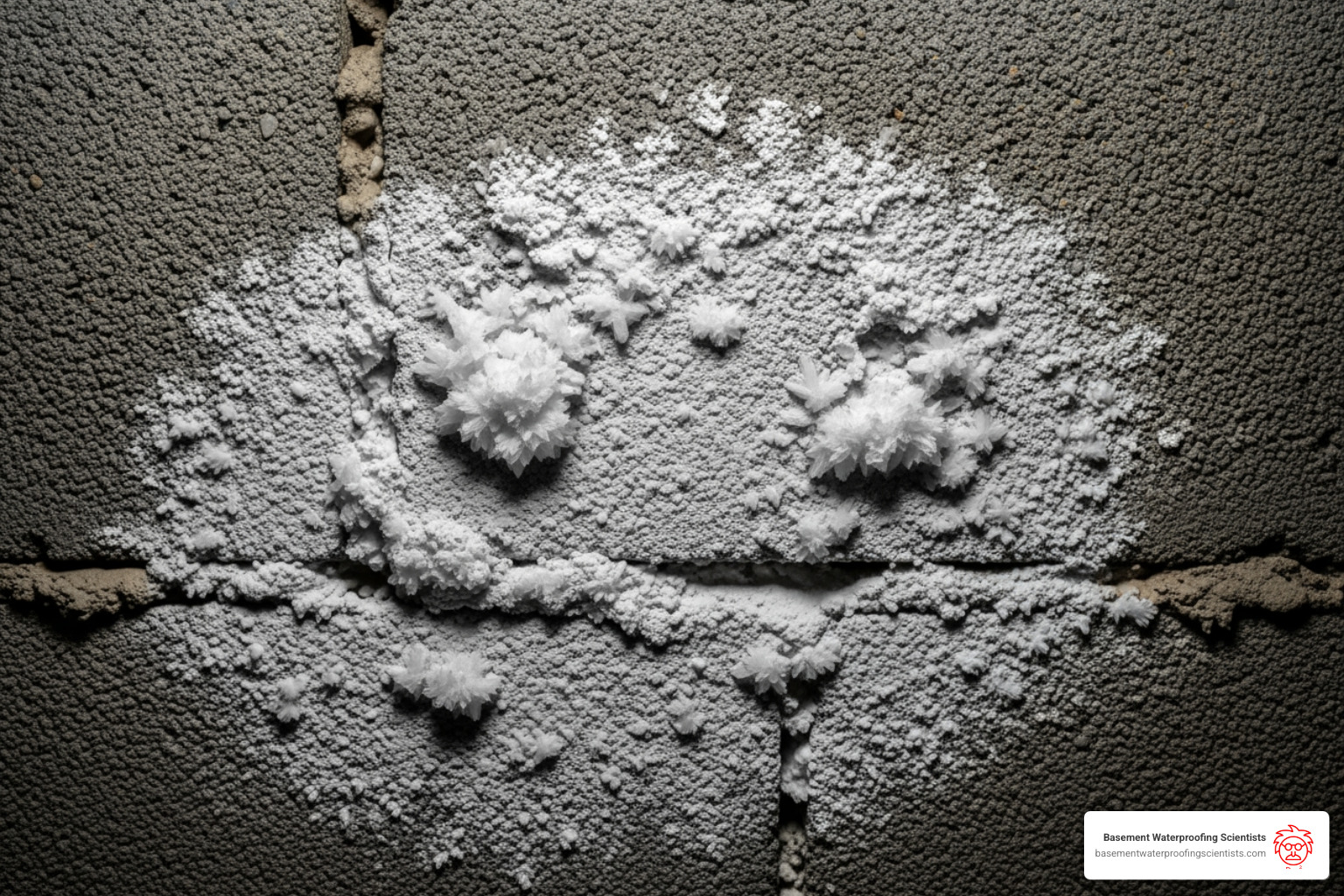

- Efflorescence: White, powdery mineral salt deposits left behind as water seeping through the block evaporates. Its presence confirms water is in your blocks.

- Damp Patches: Dark, wet spots on walls, especially after rain.

- Musty Odor: An earthy smell indicating mold or mildew growth, even if it’s not visible.

- Mold and Mildew Growth: Green, black, or white fuzzy patches on walls, floors, or stored items.

- Puddles on the Floor: Water pooling near the base of foundation walls.

- Peeling Paint: Bubbling, cracking, or flaking paint caused by moisture pushing through from behind.

If you recognize these signs in your Ardmore or Willow Grove home, it’s time to consider a cinder block foundation sealer.

The Consequences of Ignoring the Problem

Ignoring a water problem in your foundation only makes it worse and more expensive.

- Structural Integrity: Continuous water exposure, especially with Pennsylvania’s freeze-thaw cycles, compromises your foundation. Water freezes in cracks and expands, making them larger. Constant seepage can also enlarge the pores of the blocks, making them harder to seal later.

- Health Risks from Mold: A damp basement is a breeding ground for mold, which can trigger allergies and respiratory issues.

- Reduced Property Value: Water damage is a major red flag for potential home buyers.

- Damaged Belongings: Stored items, furniture, and finished spaces can be ruined by moisture.

When cracks become too large for a sealer, you may need professional Basement Wall Crack Repair. Proactively using a cinder block foundation sealer is always the smarter, cheaper choice.

Choosing the Best Cinder Block Foundation Sealer for Your Home

The best cinder block foundation sealer depends on your foundation’s condition, whether you’re sealing inside or out, and the specific problem you’re solving. It’s not a one-size-fits-all answer. For more on waterproofing products, see our guide to the Best Concrete Block Wall Waterproofer.

Here’s a quick comparison of the main sealer types:

| Sealer Type | Application | Breathability | Appearance | Best Use Case |

|---|---|---|---|---|

| Penetrating Sealers | Soaks into block pores | Yes | Natural (no film) | Preventative sealing on dry blocks; maintaining original appearance |

| Film-Forming Coatings | Creates surface layer | Varies | Visible finish | Interior walls with minor moisture; bridging hairline cracks |

| Cementitious Waterproofers | Thick cement-based coating | Limited | Semi-smooth gray | Exterior applications; resisting hydrostatic pressure; damp surfaces |

Key Differences in Cinder Block Foundation Sealer Types

Understanding the different types of cinder block foundation sealer is crucial. Each has unique strengths.

- Penetrating sealers (silane/siloxane) are our top choice for prevention. They penetrate deep into the pores and chemically react to form an internal water-repellent barrier. They don’t alter the block’s appearance and allow it to breathe, preventing moisture from getting trapped.

- Film-forming coatings (acrylic/epoxy) create a visible surface layer. They can bridge small cracks but may peel if moisture gets trapped behind them. Proper surface prep is essential.

- Cementitious waterproofers are thick, cement-based coatings mixed with water. They resist hydrostatic pressure and can be applied to damp surfaces, making them ideal for exterior use. Products like Sika Thoroseal® Plus can bridge cracks up to 1/32 inch.

- Breathable barriers are vital for cinder blocks, as they allow trapped moisture vapor to escape, preventing peeling and blistering of surface coatings.

- Elastomeric coatings are flexible coatings that stretch to bridge larger cracks, creating a seamless waterproof membrane that moves with the foundation.

- Liquid rubber membranes cure into a seamless waterproof barrier, effective for exterior below-grade foundations. For more on sealers, read our Foundation Sealer Ultimate Guide.

How Penetrating Sealers Protect from Within

Penetrating sealers use silane or siloxane compounds that soak into the block’s pores. They chemically bond with the masonry, creating an internal hydrophobic lining that repels water molecules. This process makes the block water-repellent from the inside out.

A key benefit is that they don’t form a surface film. This maintains the natural look and texture of the block, and there’s nothing to peel, flake, or wear away. They also remain breathable, allowing trapped moisture vapor to escape, which is vital for preventing recurring efflorescence and ensuring the long-term health of your foundation.

When to Use Topical Coatings and Membranes

While penetrating sealers are great for prevention, topical coatings and membranes are best for existing minor leaks, larger cracks, or exterior applications needing a robust, visible barrier.

Topical coatings provide positive-side waterproofing, meaning they are applied to the exterior to block water before it enters the foundation—like a raincoat for your house. Elastomeric coatings are thick and flexible, allowing them to bridge cracks and accommodate minor foundation movement without failing.

Liquid rubber membranes also create a durable, seamless waterproof layer. However, many topical coatings are non-breathable and can trap moisture if applied to a damp interior wall, causing them to blister and peel. For this reason, they are best suited for exterior applications. For more on this, see our insights on Exterior Foundation Sealing.

The Complete Guide to Surface Prep and Application

Proper surface preparation is more important than the cinder block foundation sealer itself. Without a clean, sound surface, even the best products will fail. This guide covers the essential steps for a lasting seal. For exterior projects, this process is even more critical, as detailed in our guide to Waterproofing Concrete Block Walls Outside.

Step 1: Cleaning and Repairing the Wall

Before sealing, the wall surface must be pristine for optimal adhesion and penetration.

- Remove Old Paint or Coatings: Old paint must be removed as it prevents sealer from penetrating or adhering properly, leading to failure. Use a wire brush, scraper, or chemical stripper.

- WARNING: If you scrape, sand or remove old paint, you may release lead dust.LEADISTOXIC.EXPOSURETOLEADDUSTCANCAUSESERIOUSILLNESS,SUCHASBRAINDAMAGE,ESPECIALLYINCHILDREN.PREGNANTWOMENSHOULDALSOAVOIDEXPOSURE. Wear a NIOSH-approved respirator to control lead exposure. Clean up carefully with aHEPAvacuu For more information on lead safety, consult the EPA guidelines.

- Clean Off Efflorescence: Remove white mineral deposits (efflorescence) with a stiff wire brush. For heavy deposits, use a specialized cleaner or muriatic acid, then rinse thoroughly.

- Pressure Washing and Degreasing: Clean the entire surface to remove all dirt, dust, and loose mortar. A pressure washer is highly effective.

- Patch Cracks and Holes: Repair cracks and holes larger than 1/32 inch with hydraulic cement (like Sika DRYLOK® Fast Plug®), which expands as it cures to create a watertight seal. Allow patches to cure fully before sealing. Our guide on Sealing Small Cracks in Foundation has more tips.

- Drying the Wall: The wall must be completely dry. For persistently wet walls, drill weeping holes in the bottom course to drain trapped water, then use fans and dehumidifiers to dry the blocks. This may take several days.

Step 2: Step-by-Step Application of a Cinder Block Foundation Sealer

With the wall prepped and dry, you can apply the cinder block foundation sealer.

- Read Manufacturer Instructions: Always read and follow the manufacturer’s instructions for temperature, drying times, and application methods.

- Gather Your Tools: You’ll need a high-quality roller (3/4-inch nap), a stiff masonry brush, or a low-pressure sprayer. Stir the product well.

- Apply the First Coat: Apply a generous first coat, using a brush to work the sealer into the block’s pores and mortar joints. For some penetrating sealers, apply the second coat “wet-on-wet” (before the first is fully dry) to maximize absorption.

- Ensure Full Coverage: Cover every spot, paying close attention to mortar joints. Most products require at least two coats for their warranty and best performance.

- Curing Times: Allow the sealer to cure completely. This can range from hours to several days. Wait at least 24 hours before backfilling an exterior wall.

Special Considerations for Challenging Walls

Some foundations require a more custom approach.

- Lightweight or Low-Cement Blocks: These blocks (e.g., split-face, Haydite) require specialized sealers that don’t rely on a chemical reaction with cement for bonding.

- Previously Saturated Walls: For highly porous or leached-out walls, drilling weeping holes to drain water and thoroughly drying the wall is essential before sealing.

- Skim Coating: On very porous walls, applying a skim coat of a cementitious product after the initial sealer can create a smoother, denser surface for the final coat.

- Multi-Layer System: For high-pressure leaks, use a multi-layer system: a deep-penetrating sealer to seal from within, followed by a topical elastomeric or cementitious coating for a robust surface barrier. This combination is highly effective for stubborn leaks.

For a detailed look at these methods, see our Concrete Block Wall Waterproofing Complete Guide.

Frequently Asked Questions about Cinder Block Foundation Sealers

Here are the most common questions we get from homeowners in Pennsylvania and New Jersey about cinder block foundation sealer solutions.

Can I apply a sealer on a painted or wet cinder block wall?

No. Sealers cannot be applied to painted or wet walls. Paint prevents the sealer from penetrating or adhering, causing it to fail. Applying a sealer over a wet wall traps moisture, which leads to blistering and peeling of the coating.

Proper surface preparation is critical. The surface must be bare, clean, and completely dry to ensure your cinder block foundation sealer works effectively and provides long-term protection.

How often do I need to reapply a cinder block sealer?

The lifespan of a sealer depends on the product type.

- Penetrating Sealers: These are the most durable, often lasting 5-10+ years. Since they seal from within the block, they don’t wear away from surface exposure. Some premium products carry warranties up to 15 years.

- Topical or Film-Forming Coatings: These surface layers wear over time and usually need reapplication every 3-5 years to maintain their effectiveness.

- Cementitious Waterproofers: These are very robust and can last over 10-20 years, especially on exterior applications where they are protected from direct wear.

Always check the manufacturer’s warranty for your specific product and inspect your walls annually to catch any issues early.

Is sealing the inside of my basement enough to stop water?

Interior sealing can manage moisture inside your basement, but it doesn’t solve the root problem. It’s a temporary fix, as water is still entering the blocks from the outside. This trapped water creates hydrostatic pressure that can eventually cause any interior coating to fail.

Exterior waterproofing is the most effective long-term solution because it stops water before it ever reaches your foundation. This involves excavating around the foundation and applying a comprehensive waterproofing system to the outside walls. While more involved, it addresses the problem at its source.

For persistent water problems, a DIY interior sealing job may not be enough. Our team uses specialized equipment to diagnose the true source of leaks, ensuring we recommend the right fix. For more on comprehensive solutions, explore our Exterior Foundation Waterproofing services.

Conclusion

Protecting your foundation with the right cinder block foundation sealer is a smart investment for any homeowner in the Philadelphia region. A proper seal does more than just keep your basement dry—it protects your home’s structural integrity, prevents mold growth for healthier indoor air, and increases your property value.

While some sealing projects are suitable for DIY, persistent leaks or complex moisture issues often require professional help. A DIY approach may not be enough to solve the underlying problem, leading to wasted time and money.

That’s where Basement Waterproofing Scientists comes in. We don’t guess. We use specialized equipment to accurately diagnose the source of leaks, allowing us to fix the real problem, often for less than broad, ineffective solutions. With 30 years of experience across Pennsylvania, New Jersey, and Delaware, we provide customized solutions backed by a lifetime guarantee.

Our expert inspections provide a clear understanding of your foundation’s condition, and our competitive pricing ensures you only pay for the work you need. If you want peace of mind about your foundation, Contact us for an inspection. We’ll help you find the best Foundation Sealant solution to protect your home for the long haul.