Understanding Basement Epoxy Paint: What You Need to Know

Basement epoxy paint is a specialized coating that transforms bare concrete floors into durable, moisture-resistant, and attractive surfaces. Unlike regular paint, epoxy creates a hard, chemical-resistant finish by bonding directly with the concrete.

Quick Comparison of Basement Epoxy Paint Options:

| Type | Best For | Durability | Cost Range | Application Difficulty |

|---|---|---|---|---|

| 1-Part Water-Based | Low-traffic DIY projects | Moderate (3-5 years) | $50-$150/gallon | Easy |

| 1-Part Solvent-Based | Medium-traffic areas | Good (5-7 years) | $100-$200/gallon | Moderate |

| 2-Part Water-Based | DIY high-traffic areas | Very Good (7-10 years) | $150-$300/kit | Moderate |

| 2-Part Solvent-Based | Professional/heavy-duty use | Excellent (10+ years) | $300-$600/kit | Difficult |

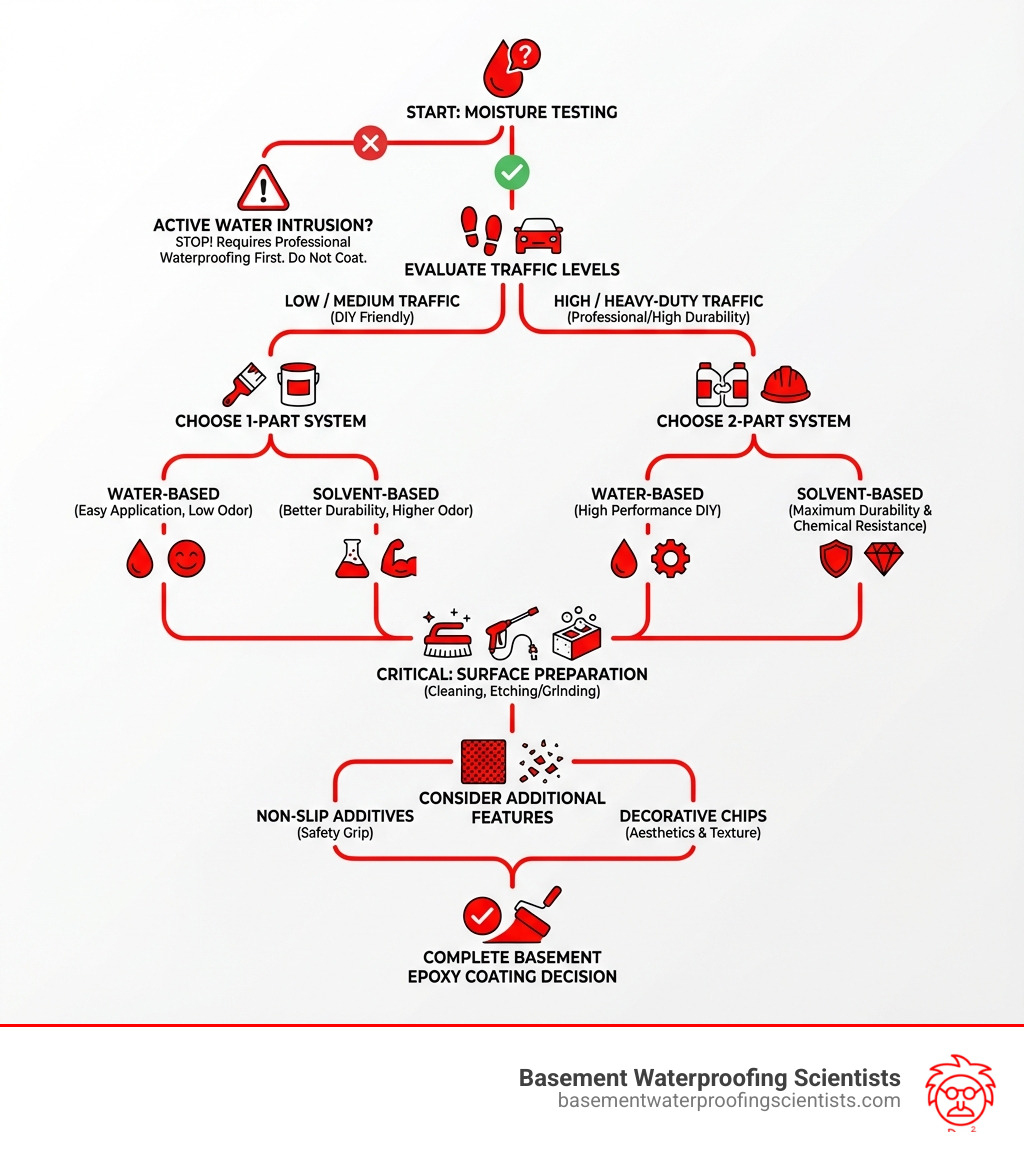

Key Considerations When Choosing Basement Epoxy Paint:

- Surface preparation is critical: The concrete must be clean, dry, and properly etched for the epoxy to bond.

- Moisture issues must be resolved first: Epoxy is a topical coating, not a waterproofing system. It will fail if applied over damp concrete or floors with active water intrusion.

- Coverage varies by product: Expect 250-400 sq ft per gallon, depending on the concrete’s porosity.

- Cure times range from 24-48 hours: Plan for extended drying periods before resuming normal use.

If your basement has active water leaks or persistent dampness, epoxy paint alone will not solve the problem. Hydrostatic pressure from groundwater can cause even the best epoxy to blister and peel. This guide covers the different types of epoxy, proper application, costs, and when a coating isn’t the right solution for your moisture problems.

What is Epoxy Floor Coating and How Does It Work?

Basement epoxy paint is not average wall paint; it’s a high-performance coating system for concrete. An epoxy floor coating is a thermoset polymer, which means it cures through a chemical reaction to form a rigid, cross-linked plastic material. This reaction begins when two components—an epoxy resin and a polyamine hardener—are mixed. The mixture creates a durable, protective layer that bonds strongly to the concrete substrate.

Unlike acrylic or latex paints that simply dry on the surface, epoxy penetrates the concrete’s pores and cures into a solid, forming a much tougher finish. Think of it as encasing your concrete in a hard, protective shell rather than covering it with a thin blanket. This chemical bond is what gives basement epoxy paint its superior performance.

For a deeper dive into the science, see our guide on Epoxy Resin Basement Floor.

The Benefits of an Epoxy Basement Floor

Choosing basement epoxy paint offers numerous advantages beyond aesthetics, which our clients in Pennsylvania, New Jersey, and Delaware appreciate:

- Exceptional Durability: Once cured, epoxy creates an incredibly hard surface that withstands heavy foot traffic, impacts, and abrasions, protecting against cracking and wear.

- Chemical and Stain Resistance: Epoxy resists spills from oils, chemicals, and cleaning agents. Spills are easy to wipe away without leaving a lasting mark.

- Effective Moisture Barrier: A properly applied epoxy coating creates a non-permeable surface, helping to prevent moisture vapor from migrating up through the concrete slab.

- Easy to Clean: The seamless, non-porous surface means dirt and dust have nowhere to hide. A simple sweep and mop are usually all that’s needed to keep it looking pristine.

- Radon Gas Reduction: Certain specialized basement epoxy paint systems are engineered to reduce radon gas levels by up to 50% by creating a sealed barrier, improving indoor air quality.

- Improved Aesthetics: Epoxy transforms a drab concrete slab into an attractive, finished floor, available in various colors and customizable with decorative chips.

- Insulation Properties: Some advanced epoxy systems offer an R4 insulation rating, contributing to a more energy-efficient and comfortable basement.

Explore more on how these coatings can revitalize your space in our guide on Basement Floor Coatings.

Potential Drawbacks and Considerations

While beneficial, basement epoxy paint has potential drawbacks:

- Slippery When Wet: A smooth, glossy epoxy surface can be slippery. This is easily mitigated by adding non-slip additives to the final coat for better traction.

- Critical Surface Preparation: The success of your epoxy floor depends almost entirely on proper surface preparation. Shortcuts in cleaning, etching, and drying the concrete can lead to peeling or premature failure.

- Peeling from Moisture Pressure: This is the most significant risk for basements. If hydrostatic pressure pushes water up through the concrete, it can cause the epoxy to blister and peel. Paint is a topical solution and will fail if applied over an underlying moisture problem.

- Limited Pot Life: 2-part epoxy systems have a limited time for application after mixing before the product begins to cure in the bucket. This requires efficient and careful planning.

- VOCs and Ventilation: Many epoxy products, especially solvent-based ones, release strong fumes (VOCs). Adequate ventilation and Personal Protective Equipment (PPE) are crucial for safety during application and curing.

Types of Basement Epoxy Paint: A Comparative Look

Choosing the right basement epoxy paint means understanding the key differences in formulations. The “solids content” refers to the percentage of epoxy resin in the product after it cures; higher solids generally mean a thicker, more durable coating.

For help selecting the ideal product, refer to our article on the Best Epoxy for Basement Concrete Floor.

Here’s a quick comparison:

| Feature/Type | 1-Part Epoxy (fortified acrylic) | 2-Part Epoxy (true epoxy) | Water-Based Epoxy | Solvent-Based Epoxy |

|---|---|---|---|---|

| Durability | Moderate (3-5 years) | Superior (7-15+ years) | Good | Excellent |

| Cost | Lower | Higher | Moderate | Higher |

| Ease of Use | Easier (pre-mixed) | More complex (mixing, pot life) | Easier (low VOC, water cleanup) | More complex (high VOC, solvent cleanup) |

| VOC Level | Low to Moderate | Variable (can be low or high) | Low to Very Low | High |

| Adhesion | Good | Excellent | Good | Excellent |

| Typical Use | Light traffic, aesthetic update | Heavy traffic, workshops | DIY, residential basements | Commercial, heavy-duty residential |

1-Part vs. 2-Part Epoxy Systems

The main distinction in basement epoxy paint is between 1-part and 2-part systems.

- 1-Part Epoxy: These are pre-mixed, user-friendly products, often a high-quality acrylic paint fortified with a small amount of epoxy. They are easier to apply and more affordable but offer lower durability. They are best for low-traffic areas or temporary cosmetic updates.

- 2-Part Epoxy: This is “true epoxy,” with a separate resin (Part A) and hardener (Part B) that must be mixed before application. This chemical reaction creates a far superior bond with superior durability, adhesion, and chemical resistance. These systems are ideal for basements that will see significant use.

Water-Based vs. Solvent-Based Epoxy

Both 1-part and 2-part epoxies come in water-based or solvent-based formulas.

- Water-Based Epoxy: These use water as the carrier for the epoxy resins. They have lower VOCs (Volatile Organic Compounds), less odor, and are easier to clean up, making them a good choice for DIY projects. However, they are generally less durable than solvent-based options.

- Solvent-Based Epoxy: These use chemical solvents as the carrier. They are known for exceptional durability, superior chemical resistance, and a harder finish. However, they have high VOC levels, requiring significant ventilation and specialized solvents for cleanup. They are often preferred by professionals for heavy-duty applications.

The DIY Guide: Prepping and Applying Your Epoxy Floor

When applying basement epoxy paint, proper preparation is 80% of the job. A successful, long-lasting finish requires a clean, dry, and porous surface for the epoxy to bond with. Skipping steps here will likely lead to floor failure.

For a detailed walkthrough, our guide on How to Epoxy a Basement Floor offers more insights.

Step 1: How to Prepare a Basement Floor for Epoxy Paint

This stage is crucial. Follow these steps carefully.

- Clean and Degrease: Thoroughly clean the floor of all dirt, dust, and debris. Use a heavy-duty degreaser for any oil or grease stains. Rinse the floor completely to remove all cleaning residues and let it dry.

- Patch Cracks and Holes: Inspect for and fill any cracks or holes with a cement-based patching compound. Allow it to cure fully per the manufacturer’s instructions for a smooth, even surface.

- Moisture Test: This is non-negotiable for basements. Tape a 12″ x 12″ piece of plastic sheeting tightly to the floor. After 24 hours, check for moisture on the underside of the plastic or discoloration of the concrete. If dampness is present, you have a moisture problem that must be addressed before applying epoxy.

- Remove Efflorescence: Treat any white, powdery mineral deposits (efflorescence) with an etching solution, then rinse and dry the surface completely.

- Etch the Concrete: The surface must be porous, like 150-grit sandpaper, for the epoxy to bond. If water beads on the surface, it needs to be etched. Acid etching is a common DIY method, while mechanical grinding provides a superior profile. Always follow safety precautions.

- Address Painted Surfaces: If the floor is already painted, remove any peeling sections and sand glossy areas to create a dull surface for the new epoxy to adhere to. Some 1-part epoxies cannot be applied over 2-part systems.

Find more tips at Prepping Basement Floor for Epoxy.

Step 2: The Application Process for Basement Epoxy Paint

With the floor prepped, you can begin applying the basement epoxy paint.

- Check Conditions: Ensure air and surface temperatures are at least 50°F. Avoid applying in direct sunlight or on hot surfaces.

- Mix (for 2-Part Systems): Precisely mix Part A (resin) and Part B (hardener) according to the manufacturer’s ratio, using a drill with a mixing paddle until uniform.

- Mind the Pot Life: Once mixed, 2-part epoxies have a limited working time (pot life), often 20-35 minutes. Work in manageable sections to avoid the product hardening in the bucket.

- Cut in Edges: Use a brush to apply epoxy along the edges of the room and around any obstacles.

- Roll the Epoxy: Pour the mixed epoxy in a line and use a 3/8-inch nap roller to spread it evenly. Work backward toward your exit.

- Apply a Second Coat: Most systems recommend two coats for best results. Allow the first coat to dry for the recommended time (e.g., 4 hours) before applying the second, often in a cross-direction to the first.

- Add Decorative Elements: If using decorative chips or non-slip additives, broadcast them into the wet final coat according to the product instructions.

See more techniques in our guide on Applying Epoxy Paint to Concrete Floor.

Step 3: Curing and Safety Precautions

After application, the epoxy must cure properly.

- Curing Times: Light foot traffic may be possible in 24 hours, but a full cure typically takes 24-48 hours at 70°F. The temperature should remain above 50°F.

- Ventilation: Proper ventilation is essential during application and curing. Open windows and use fans to circulate air and dissipate fumes.

- Personal Protective Equipment (PPE): Always wear safety glasses, gloves, and a respirator, especially with solvent-based products.

- Lead Paint Safety: If your home was built before 1978, existing paint may contain lead. Scraping or sanding can release toxic dust. Use a NIOSH-approved respirator and a HEPA vacuum for cleanup. For more information, consult the Lead safety information from the EPA.

Durability, Cost, and Maintenance of an Epoxy Floor

An investment in basement epoxy paint requires realistic expectations for longevity, cost, and care.

For a complete overview, our Basement Epoxy Floor Ultimate Guide is an excellent resource.

How Long Does Epoxy Last and What Affects Durability?

A well-applied basement epoxy paint floor can last from 5 to 15+ years, with premium systems offering warranties. Durability is affected by several factors:

- Surface Prep: This is the most critical factor. Poor preparation will cause premature failure.

- Product Quality: Epoxies with higher solids content are generally thicker and more durable.

- Foot Traffic: High-traffic areas like a home gym will show wear faster than a storage area.

- Underlying Moisture: Hydrostatic pressure pushing moisture through the concrete will cause any epoxy coating to blister and peel, drastically shortening its lifespan.

What is the Cost of a Basement Epoxy Floor?

The cost of a basement epoxy paint project varies based on a DIY vs. professional approach and the materials used.

- DIY Kit Cost Range: For a standard 250-300 sq ft basement, DIY kits can range from $100 to over $500. Cost-effective 1-part epoxies are at the lower end, while advanced 2-part systems are at the higher end.

- Professional Installation Cost: Hiring a professional includes the cost of labor, specialized equipment (like grinders), and expertise. The final price is influenced by the basement’s size, the concrete’s condition (requiring extensive prep), the type of epoxy system, and any decorative additions.

- Factors Influencing Price: The key variables are the size of the area, the amount of prep work needed, the quality of the epoxy system, and decorative options like color flakes or metallic pigments.

For more detailed cost breakdowns, visit our page on Basement Epoxy Floor Cost.

Maintaining Your New Epoxy Floor

One of the best features of basement epoxy paint is its low maintenance.

- Routine Cleaning: Regular sweeping or vacuuming is sufficient for dust. For general cleaning, use a mop with warm water and a mild, pH-neutral cleaner.

- Avoid Harsh Tools: Do not use abrasive pads, steel wool, or harsh chemical cleaners, as they can dull or damage the finish.

- Protect from Impacts: While durable, heavy impacts can chip the surface. Use floor mats in high-impact zones like workshops or gyms.

- Clean Spills Promptly: Although stain-resistant, it’s best to wipe up spills quickly, especially harsh chemicals.

When Epoxy Isn’t Enough: Integrating with Waterproofing Solutions

At Basement Waterproofing Scientists, our expertise shows that while basement epoxy paint is a fantastic flooring solution, it has critical limitations. It is a topical sealer, not a comprehensive waterproofing system, and it cannot stop water intrusion.

The primary issue in basements is often hydrostatic pressure—the force of groundwater pushing through foundation walls and floors. Applying a coating over a surface with this issue is a recipe for failure. The trapped moisture will build up behind the epoxy layer, causing it to blister, peel, and delaminate. We have seen this scenario countless times across Pennsylvania, New Jersey, and Delaware, where homeowners apply a coating to solve a dampness problem, only to face more expensive repairs later.

If you have active leaks, persistent dampness, or visible moisture, applying epoxy without addressing the root cause is like putting a band-aid on a major wound. It may look better temporarily, but the underlying problem will worsen.

For true basement protection, explore how coatings can be integrated with proper waterproofing on our Epoxy Basement Floor Waterproofing page.

Comparing Epoxy to Other Basement Flooring

Is basement epoxy paint the right choice for you? Here’s a quick comparison:

- Epoxy vs. Concrete Sealers: Epoxy is a thick, durable, non-porous coating that offers superior aesthetics and protection. Sealers are thinner, protect against moisture and stains, but lack the durability and finish of epoxy.

- Epoxy vs. Stains: Epoxy creates an opaque, uniform protective layer. Stains penetrate the concrete for a translucent, variegated color and require a separate sealer for protection.

- Epoxy vs. Tiles (Ceramic/Porcelain): Epoxy is seamless and chemically resistant. Tiles offer many aesthetic options, but grout lines can trap moisture and stain. Installation is also more complex.

- Epoxy vs. Luxury Vinyl Plank (LVP): Epoxy is a seamless, bonded, waterproof surface. LVP is a floating floor that feels warmer but can trap moisture underneath if a proper vapor barrier isn’t used.

Can Epoxy Paint Fix a Leaky Basement?

The short and definitive answer is no, basement epoxy paint cannot fix a leaky basement.

Here’s why:

- Topical vs. Structural: Epoxy is a surface coating. It does not fix structural issues like foundation cracks or stop the hydrostatic pressure that forces water through concrete.

- Blistering and Peeling: Water pressure from below will get under the epoxy, break its bond with the concrete, and cause it to bubble and peel away, creating a bigger mess.

- Foundation Cracks: Sealing significant foundation cracks with epoxy paint is ineffective. These issues require professional repair, such as polyurethane injection, to properly seal the crack and stop water intrusion.

Addressing the root cause of water entry first is essential. If your basement shows any signs of water, a professional inspection is needed before considering any decorative floor coating.

Conclusion: Making the Final Decision for Your Basement Floor

Choosing the right flooring is a key decision, and basement epoxy paint offers a compelling mix of durability, aesthetics, and low maintenance. We’ve covered its benefits, drawbacks, and the critical importance of surface preparation.

For a dry, well-maintained basement, a high-quality 2-part epoxy system can transform a concrete slab into a vibrant, functional floor. It can be an excellent DIY project or a smart professional investment when applied correctly.

However, the most crucial takeaway from our 30+ years of experience in the Philadelphia, Reading, and Norristown areas is this: a coating is not a cure for moisture problems. No basement epoxy paint, no matter how advanced, can waterproof a basement with active leaks or significant hydrostatic pressure. Applying it in these conditions will lead to wasted money and a failed floor.

If your basement shows signs of water intrusion—damp spots, mold, or leaks—we strongly urge you to consult a professional. Our team at Basement Waterproofing Scientists specializes in identifying leak sources and providing permanent waterproofing solutions. An average waterproofing project costs between $4K and $8K, a vital investment to protect your home’s foundation before any cosmetic upgrades.

Once your basement is truly dry, then you can choose the perfect basement epoxy paint to complete your vision. Address the root cause first to enjoy a beautiful, worry-free basement floor for years to come.

To learn how we can help you achieve a permanently dry basement, explore our professional solutions: Explore professional basement floor coating solutions