Why Concrete Wall Crack Repair Epoxy Injection Matters for Your Home

Concrete wall crack repair epoxy injection is a proven method to restore structural integrity to cracked foundation and basement walls. The process involves filling cracks with a high-strength, two-part epoxy resin under low pressure. Here’s a quick overview:

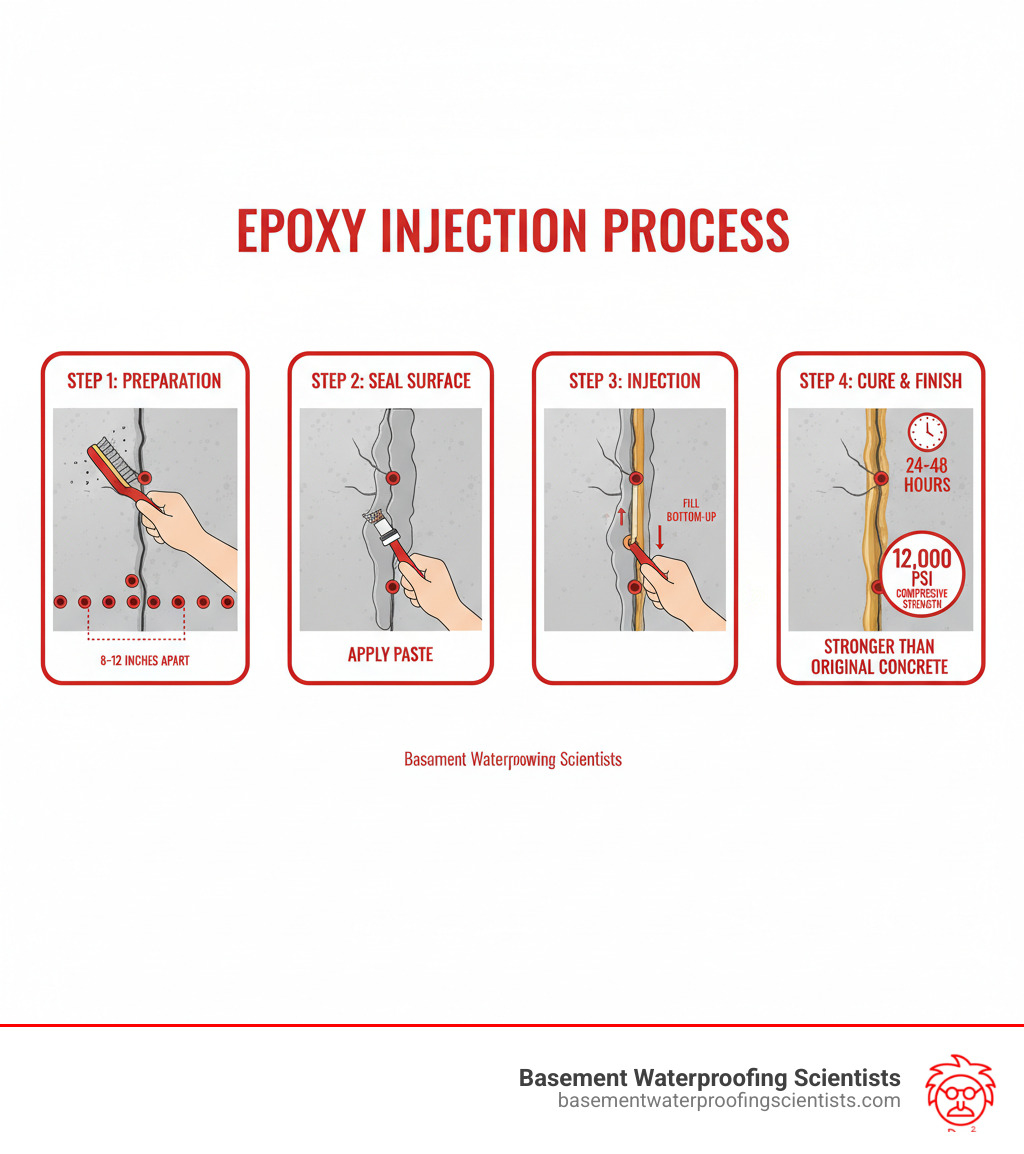

The Epoxy Injection Process

- Clean and prepare the crack surface.

- Install injection ports along the crack.

- Apply a surface seal to contain the epoxy.

- Inject epoxy resin from the bottom up.

- Allow to cure for 24-48 hours.

Best For: Dormant structural cracks (hairline to 1/4 inch) in poured concrete walls.

Compressive Strength: 12,000 PSI (stronger than concrete).

Expected Lifespan: Permanent when properly applied.

For over 30 years, epoxy injection has been used to seal cracks as narrow as 0.002 inches, creating structural bonds stronger than the concrete itself. However, not all cracks are suitable for epoxy. Active leaks, moving cracks, and hollow block walls require different methods. Using the wrong approach can waste money and leave your basement vulnerable to water damage, pests, and radon gas.

Ignoring foundation cracks is costly. A DIY epoxy kit costs $229 to $480, but ignoring a structural problem can lead to repairs costing $11,000 or more. For comparison, comprehensive basement waterproofing typically costs between $4,000 and $8,000.

I’m Darin Garvey of Basement Waterproofing Scientists. With decades of experience, I’ve seen how effective epoxy injection is when applied correctly. We use professional-grade materials and specialized equipment to ensure your repair lasts a lifetime.

Understanding Concrete Wall Cracks: Causes and Types

Not all foundation cracks signal disaster. Understanding their cause is key to choosing the right repair. After three decades of inspecting foundations in Pennsylvania, New Jersey, and Delaware, I’ve seen what causes concrete to crack.

Common Causes of Foundation Cracks:

- Foundation settlement: Uneven soil compaction causes sections of the house to sink, stressing the concrete.

- Concrete shrinkage: As concrete cures and loses water, it naturally contracts and can form hairline cracks.

- Hydrostatic pressure: Saturated soil exerts immense inward pressure on basement walls, leading to cracks.

- Lateral soil pressure: Expansive soils, like clay, swell when wet and shrink when dry, stressing the walls.

- Freeze-thaw cycles: Years of expansion and contraction from temperature changes can fatigue and crack concrete.

- Poor construction: Cold joints (improperly integrated concrete pours) or overloading the foundation create weak points.

The crack’s pattern tells a story. Hairline cracks (under 1/8 inch) are often from shrinkage. Vertical cracks with a consistent width may indicate normal settling. Diagonal cracks suggest differential settlement, where one part of the foundation is sinking faster than another. Horizontal cracks are red flags, signaling significant external pressure that requires immediate professional assessment. In block foundations, stair-step cracks point to settlement or soil pressure. Any crack wider than 1/4 inch or actively growing demands urgent evaluation.

For more on minor issues, see our guide on small foundation cracks.

What Types of Cracks Require Concrete Wall Crack Repair Epoxy Injection?

Concrete wall crack repair epoxy injection is a specialized tool, not a universal fix. It is ideal for dormant, structural cracks (hairline to 1/4 inch wide) in poured concrete walls. The crack must be dry for the epoxy to create a rigid, structural bond. With a compressive strength of around 12,000 PSI, the repair becomes stronger than the surrounding concrete, fully restoring the wall’s load-bearing capacity.

If you’re evaluating damage, our Basement Wall Crack Repair Guide offers detailed criteria.

When to Avoid Epoxy and Consider Alternatives

Using epoxy in the wrong situation is a waste of time and money. Here’s when to avoid it:

- Actively leaking cracks: Epoxy won’t bond to wet surfaces. Use polyurethane injection, which reacts with water to form a seal.

- Moving or expanding cracks: A rigid epoxy repair will fail if the wall continues to shift. The root cause must be addressed first.

- Hollow concrete block walls: Epoxy is not designed for hollow block construction, which requires different methods.

- Very wide cracks (>1/4 inch): These often require alternative repair methods or specialized high-viscosity products.

- Cracks from corroding rebar: The underlying corrosion must be addressed first, as it will break through any surface repair.

Understanding the difference between moisture control and waterproofing is key. Our comparison of Damp Proofing vs Waterproofing can help clarify your needs.

A Step-by-Step Guide to Concrete Wall Crack Repair Epoxy Injection

Performing concrete wall crack repair epoxy injection requires precision and the right tools. Whether DIY or professional, understanding the process is key to a lasting structural repair.

A typical epoxy injection kit includes two-part epoxy resin, a surface sealer paste, injection ports, mixer nozzles, and application tools. Professional-grade epoxies meeting ASTM C881 standards can achieve compressive strengths of 12,000 PSI, exceeding that of concrete. The process uses low-pressure injection (50-100 PSI) for most cracks, though high pressure may be needed for very fine cracks. For a visual walkthrough, see this APPLICATION VIDEO for DIY FOUNDATION CRACK REPAIR.

Step 1: Surface Preparation and Safety

A clean surface is essential for a strong bond. Use a wire brush to remove all loose debris, dirt, old paint, and efflorescence from the crack and about half an inch on each side. The surface must be as dry as possible, as most epoxies are moisture-sensitive. If the concrete is deteriorated, you may need to cut a shallow V-groove to reach sound material.

Safety is paramount. Always:

- Wear proper protective equipment, including gloves, safety glasses, and protective clothing. Use a respirator in poorly ventilated areas.

- Ensure good ventilation to prevent fume buildup.

- Read the Material Safety Data Sheets (MSDS) before starting.

Step 2: Installing Injection Ports and Applying the Surface Seal

This step creates the delivery system for the epoxy. Place plastic injection ports directly over the crack, spaced 8 to 12 inches apart. Use the epoxy paste (surface sealer) to secure the base of each port. Then, apply a continuous bead of the sealer over the entire crack length, covering the crack and port bases to create a dam. Keep the port openings clear. Allow the seal to cure until it’s firm to the touch.

Step 3: Injecting the Epoxy Resin

Now, the epoxy penetrates the crack to bond the concrete. If using a cartridge system, the two parts mix automatically. Otherwise, mix the components according to the manufacturer’s exact instructions.

Always start at the lowest port on a vertical crack. Apply steady, low pressure. Watch for epoxy to flow out of the next port up—this indicates the section is full. Cap the port you just finished and move to the next one. Continue this process up the crack until it is completely saturated and will not accept any more epoxy.

Step 4: Curing and Finishing

Patience during curing ensures a permanent repair. Most epoxies need 24 to 48 hours to fully cure, though temperature can affect this time. A properly executed epoxy injection can last for the life of your home, 30 years or more.

Once cured, remove the injection ports and surface seal with a chisel or scraper. For a clean, professional finish, grind any residual material flush with the concrete surface. The repaired area can then be painted.

For more on other repair methods, explore our guide to 7 Top-Rated Foundation Repair Techniques for Homeowners in 2024.

Epoxy vs. Polyurethane Injection: Which is Right for Your Crack?

When facing a foundation crack, the two dominant repair methods are epoxy and polyurethane injection. Though both involve injecting a resin, they serve very different purposes. Epoxy injection provides a structural bond, while polyurethane injection creates a flexible, waterproof seal. Choosing the right one is critical for a lasting repair and can save you from costly re-dos.

| Feature | Epoxy Injection | Polyurethane Injection |

|---|---|---|

| Primary Function | Structural bonding and waterproofing | Flexible sealing and waterproofing |

| Material Type | Rigid, high-strength resin | Flexible, expanding foam/gel resin |

| Crack Type | Dormant, non-moving, structural cracks | Active leaks, moving cracks, non-structural cracks |

| Conditions | Best for dry cracks | Reacts with water, ideal for wet/leaking cracks |

| Viscosity | Varies (low for hairline, higher for wider cracks) | Low (penetrates fine cracks, expands when wet) |

| Outcome | Restores original concrete strength (12,000 PSI) | Creates a watertight, flexible seal that accommodates movement |

| Best Use Cases | Rebonding structural elements, preventing future cracking, dry basement walls | Stopping active water leaks, sealing cracks in foundations subject to movement, wet basement walls |

Concrete wall crack repair epoxy injection is the champion of structural repair. It cures into a rigid solid with a compressive strength of 12,000 PSI, making the repaired section stronger than the surrounding concrete. This makes it the perfect choice for dry, dormant cracks in poured concrete walls where restoring strength is the primary goal.

However, epoxy is rigid and moisture-sensitive, so it will fail if used on a moving or actively leaking crack.

Polyurethane injection is designed for waterproofing. It reacts with water and expands (up to 20 times its volume) to form a flexible, rubbery seal that aggressively stops active leaks. Because it remains flexible, it can accommodate minor foundation movement without breaking the seal, making it ideal for wet or non-structural cracks. The trade-off is that polyurethane does not add structural strength.

At Basement Waterproofing Scientists, we don’t guess. We use specialized equipment to determine if a crack is stable or moving and whether it’s wet or dry. This diagnostic approach, refined over 30 years, allows us to select the right material for your specific situation—epoxy for strength or polyurethane for flexible waterproofing. Sometimes a hybrid approach is best. The bottom line is that a correct diagnosis is key to a permanent repair.

DIY vs. Professional Repair: Cost and Considerations

When you find a crack in your basement wall, you have to decide between a DIY project and calling a professional. Let’s break down the costs and factors to consider.

The Money Question

DIY epoxy injection kits range from around $67 for small jobs to $480 or more for comprehensive systems. Professional concrete wall crack repair epoxy injection for a single crack typically costs a few hundred dollars. For more extensive issues or full basement waterproofing, homeowners usually invest between $4,000 and $8,000. While this seems steep, ignoring a structural crack can lead to future repairs costing over $11,000. As detailed in our guide to Leaking Basement Wall Repair Cost, fixing problems correctly and early saves money.

Key Considerations for DIY Concrete Wall Crack Repair Epoxy Injection

DIY repair can work, but only for the right type of crack. The biggest challenge is accurate assessment. Is the crack structural, dormant, and in a poured concrete wall? Getting this wrong leads to a failed repair.

Precise application is also critical. The surface must be clean, ports spaced correctly (8-12 inches), and the seal must be cured. Common DIY pitfalls include incomplete fills, seal failure under pressure, and using the wrong material for the job, like applying rigid epoxy to a moving crack. For other DIY approaches, see our DIY Carbon Fiber Foundation Repair Tips.

When to Call a Professional

Some cracks are clear signals to call an expert. Attempting a DIY repair on these can be risky.

- Horizontal cracks: Almost always indicate significant structural stress from external pressure.

- Wide or expanding cracks: Anything over 1/4 inch or visibly growing suggests ongoing movement.

- Multiple cracks: This pattern often points to widespread foundation distress.

- Bowing or buckling walls: These represent critical structural failure and require immediate intervention.

- Active leaks: These require specialized waterproofing, likely with polyurethane, not epoxy.

- Block walls: These need different repair methods than poured concrete.

- When you’re uncertain: Don’t guess. A professional diagnosis prevents costly mistakes. As we discuss in our guide on when to fix basement wall cracks, getting the repair right the first time is what matters.

At Basement Waterproofing Scientists, we’ve spent 30 years perfecting repairs across Philadelphia, Reading, Norristown, Pottstown, Bensalem Township, Upper Darby Township, Bristol Township, Middletown Township, Lansdale, Warminster Township, Springfield Township, Haverford Township, Radnor Township, Willow Grove, King of Prussia, Horsham, Exeter Township, Cumru Township, Ardmore, Bryn Mawr, Quakertown, Royersford, Conshohocken, Hatboro, Collegeville, and throughout Pennsylvania, New Jersey, and Delaware. We use specialized equipment to find the exact leak source, allowing us to fix them for less with a lifetime guarantee.

Conclusion

Concrete wall crack repair epoxy injection is a powerful solution for restoring structural integrity to foundation walls. When applied to the right type of crack, it creates a bond that is stronger than the original concrete, turning a weakness into a strength and preventing far more expensive damage down the road.

However, success depends entirely on using it in the right scenario. Epoxy is for dormant, structural cracks in poured concrete. An actively leaking or moving crack requires a different solution, like flexible polyurethane. Choosing the wrong method leads to a failed repair, wasted money, and a false sense of security.

While DIY kits can work for minor cracks, foundation repair is often more complex than it appears. A horizontal crack or a bowing wall is a sign of serious underlying issues that demand a professional diagnosis.

This is why at Basement Waterproofing Scientists, we eliminate the guesswork. With 30 years of experience and specialized leak detection equipment, we identify the root cause of your foundation problems. This diagnostic approach allows us to provide targeted, cost-effective repairs backed by a lifetime guarantee.

Foundation problems only get worse and more expensive over time. Whether you need a single crack sealed or comprehensive waterproofing (which typically costs between $4,000 and $8,000), addressing the issue early is the most affordable path. If you’re looking at a crack in your basement wall, don’t guess what it means for your home.

Schedule your professional foundation repair assessment today and get the expert diagnosis and permanent solution your home deserves.