Why Protecting Your Basement Foundation Matters More Than Ever

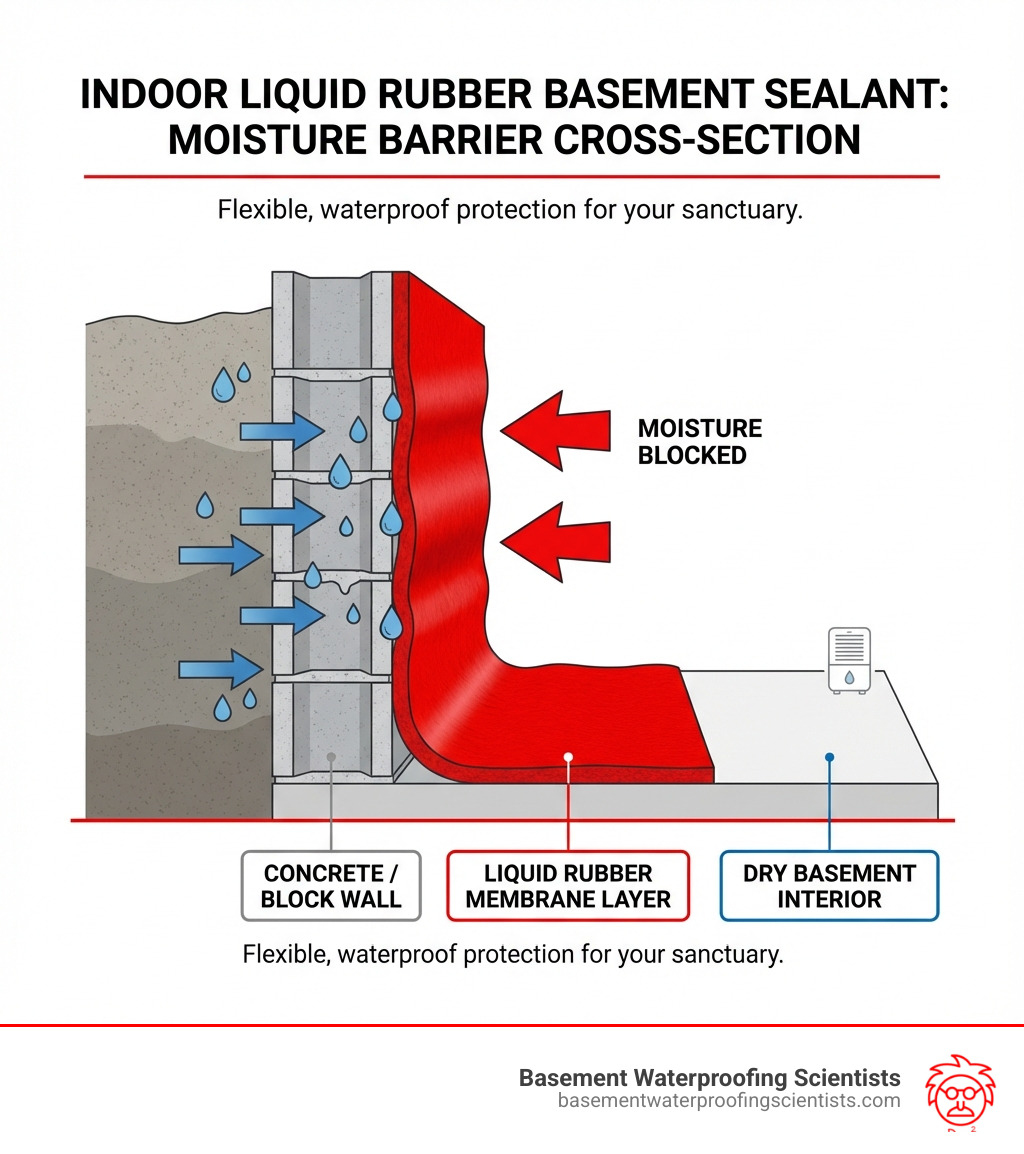

Liquid rubber concrete foundation and basement sealant – indoor is a water-based, elastomeric coating that creates a seamless, flexible waterproof membrane on interior basement surfaces to prevent moisture intrusion, mold growth, and structural damage.

Quick Facts About Indoor Liquid Rubber Sealants:

- What it is: A flexible, rubber-like coating that bonds to concrete, block, and masonry

- Key benefit: Creates a waterproof barrier with up to 1800% expansion/contraction to resist cracking

- Safety: Non-toxic, VOC-free, safe for confined indoor spaces

- Coverage: Approximately 1 gallon per 50 square feet for interior walls

- Application: DIY-friendly with roller or brush, requires 2-3 coats

- Cost advantage: Materials-only approach vs. professional waterproofing ($4K-$8K average)

If you’ve dealt with damp basement walls, musty odors, or white powdery stains, you’re not alone. According to HomeAdvisor, homeowners spent an average of $9,081 on home improvement projects in 2018, with basement waterproofing ranking among the top concerns. The good news? Modern liquid rubber technology has made protecting your foundation from the inside more accessible than ever.

Traditional basement waterproofing methods often involved messy, solvent-based products or expensive professional installations. Today’s liquid rubber sealants offer a different path—one that homeowners can tackle themselves while achieving professional-grade results. These products create a flexible, breathable barrier that moves with your foundation, sealing out moisture while allowing trapped water vapor to escape.

As Darin Garvey, owner of Basement Waterproofing Scientists with over 30 years of combined team experience in the Philadelphia area, I’ve seen how liquid rubber concrete foundation and basement sealant – indoor applications can transform damp, unusable spaces into dry, healthy environments. The key is understanding what these products do, how to apply them correctly, and when professional intervention makes more sense.

Let’s explore how this modern solution works and whether it’s the right choice for your basement.

Liquid rubber concrete foundation and basement sealant – indoor terms at a glance:

Understanding Liquid Rubber: The Modern Solution for a Dry Basement

A solid, dry basement is more than just a luxury; it’s a fundamental component of a healthy, structurally sound home. For us, ensuring your basement remains dry is about protecting your investment, safeguarding your family’s health, and expanding your usable living space. When moisture creeps in, it doesn’t just make things feel damp; it can compromise the structural integrity of your home, leading to costly repairs down the line. Beyond that, a damp environment is a breeding ground for mold and mildew, which can trigger allergies, respiratory issues, and create unpleasant, musty odors. By keeping your basement dry, we help you maintain a healthy living environment, protect cherished belongings, and even increase your home’s overall value.

What is Liquid Rubber Sealant?

At its core, liquid rubber concrete foundation and basement sealant – indoor is an innovative elastomeric coating. Imagine a thick, paint-like substance that, once applied, cures into a highly flexible, rubbery membrane. Unlike rigid paints or sealers that can crack with foundation movement, liquid rubber is designed to move with your home. It’s typically water-based, meaning it doesn’t contain harsh solvents, which is a huge plus for indoor applications.

This sealant creates a seamless, watertight barrier that adheres tenaciously to various surfaces. One of its most impressive characteristics is its high elongation — some products boast up to 900% or even 1800% elongation. This incredible flexibility allows the sealant to stretch and contract significantly without cracking or peeling, effectively bridging hairline cracks and accommodating the natural settling and movement of your foundation. It’s essentially a continuous, protective skin for your basement walls.

Key Benefits for Indoor Basement Applications

When considering waterproofing solutions for your interior basement, liquid rubber concrete foundation and basement sealant – indoor offers a compelling list of advantages:

- Creates an Impenetrable Waterproof Barrier: This is its primary superpower. Once cured, it forms a robust membrane that stops moisture in its tracks, preventing it from seeping through porous concrete or cinder blocks.

- Stops Moisture, Prevents Mold and Mildew: By blocking moisture, liquid rubber directly combats the conditions necessary for mold and mildew growth. This is crucial for maintaining healthy indoor air quality and eliminating those tell-tale musty basement odors. We’ve even heard anecdotal evidence from homeowners in areas like Norristown and King of Prussia reporting a decrease in spiders and bugs after sealing their basement walls, suggesting a drier, less inviting environment for pests.

- Safe for Indoor Use: This is a critical benefit for interior applications. Many liquid rubber products are non-toxic, VOC-free, and eco-friendly, making them compliant in all 50 states, including Pennsylvania, New Jersey, and Delaware. This means you can apply them in confined basement spaces without worrying about harmful fumes or compromising your family’s health.

- Eco-Friendly: Being water-based and free of harsh chemicals, these sealants offer a greener approach to home waterproofing.

How Liquid Rubber Addresses Common Basement Issues

Basements often face a variety of moisture-related challenges. Liquid rubber concrete foundation and basement sealant – indoor is uniquely equipped to tackle many of these:

- Seals Porous Concrete: Concrete and cinder block walls are inherently porous, allowing water vapor and even liquid water to pass through. Liquid rubber coats these surfaces, effectively sealing off countless microscopic pathways for moisture.

- Bridges Hairline Cracks: As foundations settle and age, hairline cracks are almost inevitable. The extreme elasticity (up to 1800% expansion and contraction) of liquid rubber allows it to stretch over these minor imperfections, preventing them from becoming entry points for water.

- Resists Hydrostatic Pressure: While it’s crucial to address exterior drainage, liquid rubber provides an interior defense against the pressure of water in the soil pushing against your foundation. It creates a robust barrier that can withstand this pressure, preventing water from being forced through the walls.

- Prevents Efflorescence: Have you ever seen white, powdery deposits on your basement walls? That’s efflorescence – mineral salts left behind as water evaporates from the concrete. Liquid rubber acts as a barrier, preventing the water from reaching the surface and thus stopping efflorescence.

- Reduces Musty Odors: Musty odors are a dead giveaway of mold and mildew. By creating a dry environment and inhibiting microbial growth, liquid rubber significantly reduces or eliminates these unpleasant smells, contributing to a fresher, healthier basement.

For a deeper dive into the science of waterproofing, explore our guide on concrete foundation waterproofing.

Preparing Your Basement Walls for a Flawless Seal

Just like a chef knows the importance of mise en place, we know that proper preparation is the secret ingredient for any successful DIY project, especially when it comes to waterproofing your basement. A strong bond between the sealant and your wall is paramount, and that only happens with a clean, well-prepared surface. Skipping this step is like trying to paint over rust – it just won’t last.

Step 1: Clean and Inspect the Surface

Before you even think about opening that bucket of liquid rubber concrete foundation and basement sealant – indoor, your basement walls need a spa day.

- Remove the Old and Loose: Start by removing any loose paint, flaking sealants, or crumbling debris. A wire brush, scraper, or even a power washer (if you have good drainage) can be your best friends here. The goal is to get down to a solid, stable surface.

- Clean Away Dirt and Debris: Dust, dirt, and cobwebs are not conducive to good adhesion. Use a stiff brush and a good cleaner (like a deck and patio cleaner, or even just a strong detergent solution) to thoroughly scrub the walls. Rinse well and allow to dry completely.

- Identify Moisture Sources: While cleaning, pay close attention to where moisture might be coming from. Are there damp spots, dark stains, or persistent puddles? This inspection helps us understand the extent of the problem.

- Check for Stains: Different stains tell different stories. White, powdery efflorescence indicates mineral salts. Reddish or orange stains might point to iron ochre. Dark, grayish stains are usually mold or mildew.

- Mold and Mildew Removal: If you find mold, it needs to be addressed properly. For smaller areas (less than 10 square feet, roughly 3×3 ft), you can clean it yourself using a solution of 12 ounces of bleach per gallon of water. Always wear protective gear (gloves, eye protection, mask) and ensure good ventilation. For larger infestations, the EPA and CDC recommend professional help. It’s better to be safe than sorry! You can find detailed guidance in the EPA guidelines for mold cleanup.

Step 2: Repair Cracks and Imperfections

Now that your walls are sparkling clean (or at least, clean enough for a basement!), it’s time to play doctor and fix any wounds.

- Hydraulic Cement for Larger Cracks: For wider cracks (larger than 1/8 inch), hydraulic cement is an excellent choice. It sets quickly and expands as it cures, creating a tight seal. Apply it with a trowel, making sure to wipe away any excess before it hardens.

- Sealant Caulk for Joints and Voids: For smaller cracks, gaps, or around pipe penetrations, a high-quality sealant caulk (like a liquid rubber sealant and adhesive caulk) is perfect. This can fill voids larger than 1/8″ up to 1/2″ deep before applying the main sealant.

- Geotextile Fabric for Reinforcement: For seams, joints, or areas with persistent movement, geotextile fabric embedded in the liquid rubber provides extra reinforcement. This “3-course method” is similar to taping drywall joints and adds significant strength and crack-bridging capability.

- Creating a Smooth Surface: The goal is a relatively smooth, even surface for the liquid rubber to adhere to. Any major protrusions or depressions should be smoothed out as much as possible.

For comprehensive advice on addressing these issues, consult our guide on sealing foundation cracks.

Step 3: When to Use a Primer

While many liquid rubber sealants are designed to adhere directly to bare concrete, there are situations where a primer is a very wise investment for your liquid rubber concrete foundation and basement sealant – indoor project:

- Applying Over Existing Paint/Coatings: If your basement walls have old paint or coatings that are still well-adhered, you can often apply liquid rubber over them. However, it’s highly recommended to use a multi-purpose primer first. This improves adhesion and ensures your new liquid rubber coating bonds securely. Just be aware: if the original coating eventually peels, your new liquid rubber coating will likely peel with it, as it’s bonded to the old paint, not the concrete itself. We always recommend removing oil-based or recently applied coatings if possible.

- Enhancing Adhesion and Longevity: Even on bare concrete, a primer can significantly improve the bond, especially in interior basement applications where moisture vapor drive (moisture pushing from the outside in) is a factor. A primer creates a more stable, consistent surface for the liquid rubber to bond to, contributing to the overall performance and longevity of your waterproofing system.

- Creating a Moisture Vapor Barrier: Some primers are specifically designed to act as an additional moisture vapor barrier, adding another layer of defense against dampness.

When in doubt, a test patch with and without primer in an inconspicuous area can give you a good indication of adhesion.

The Application Process for Liquid Rubber Concrete Foundation and Basement Sealant – Indoor

Ready to transform your damp basement into a dry, usable space? Applying liquid rubber concrete foundation and basement sealant – indoor is a remarkably DIY-friendly process. With proper preparation and a little patience, you can achieve professional-grade results. Just remember to always follow the manufacturer’s specific instructions for the product you choose.

Tools and Materials Checklist

Before you begin, gather your arsenal of supplies. It’s always a good idea to have everything ready to go:

- Liquid rubber sealant: The star of the show! Make sure you have enough for 2-3 heavy coats.

- Paint roller: A 3/8-inch (10mm) nap roller is generally recommended for even application on concrete.

- Paintbrush: Essential for cutting in corners, edges, and around pipes.

- Roller tray: For easy loading of the roller.

- Painter’s tape: To protect adjacent surfaces (like floors or trim) and create clean lines.

- Safety glasses: To protect your eyes from splashes.

- Gloves: To keep your hands clean and protected.

- Cleaning supplies: Rags, brushes, and a bucket for water-based cleanup.

- Stir stick: To thoroughly mix the sealant before and during application.

- Optional: A paint sprayer can be used for larger areas, but ensure it’s compatible with thick, elastomeric coatings.

Applying the Liquid Rubber Concrete Foundation and Basement Sealant – Indoor

With your tools ready and walls prepped, it’s time for the main event:

- Stir Thoroughly: Before you begin, stir the liquid rubber sealant thoroughly. It’s thick, so you’ll want to ensure all components are well mixed.

- Temperature Matters: Apply the sealant when temperatures are above 50°F (10°C) and when rain or heavy dew isn’t expected for at least 24-48 hours. While this is an indoor application, extreme cold can affect curing.

- Apply Thin, Even Coats: Resist the urge to apply one super-thick coat. It’s far better to apply multiple thin, even coats. For interior walls, we typically recommend applying approximately 1 gallon of sealant per 50 square feet of space. This usually translates to two to three heavy coats to achieve the recommended final thickness of 20 mil (0.5-0.76mm) dry film thickness.

- Alternating Coat Direction: For optimal coverage and to ensure a seamless membrane, apply each subsequent coat in an alternate direction to the previous one (e.g., if the first coat was vertical, apply the second horizontally).

- Drying Time Between Coats: Patience is a virtue here. Allow each coat to dry completely to the touch and appear uniform in color before applying the next. This usually takes 12-24 hours, depending on humidity and temperature. Applying too soon can lead to bubbling or improper curing.

- Corners and Edges: Use your paintbrush to carefully apply the sealant in corners, along edges, and around any obstacles where the roller can’t reach. Ensure these areas get the same coverage as the main wall.

Curing and Finishing Your Project

You’re almost there! The final steps involve allowing the sealant to cure and deciding on any additional finishes.

- Final Cure Time: While dry to the touch in hours, liquid rubber typically achieves its initial cure in 24-48 hours. Full cure, where it reaches maximum strength and flexibility, can take longer, sometimes several days to a week, depending on conditions.

- Removing Painter’s Tape: If you used painter’s tape, remove it while the final coat is still wet or tacky. Waiting until it’s fully cured can cause the sealant to peel along with the tape, leaving jagged edges.

- Can You Paint Over It?: Absolutely! Many liquid rubber concrete foundation and basement sealant – indoor products can be painted over. If you’ve used a black foundation sealant and prefer a different aesthetic, you can apply an acrylic latex paint as a topcoat. This allows you to customize the look of your basement while retaining the waterproofing benefits.

- Using as a Base for Other Finishes: While liquid rubber creates a durable, finished surface on its own, it can also serve as a base for other finishes. However, always check the manufacturer’s recommendations if you plan to install drywall, paneling, or other materials directly over the sealed surface to ensure compatibility and proper adhesion.

Why Choose Liquid Rubber Over Outdated Methods?

For decades, homeowners in areas like Philadelphia, Reading, and Lansdale have battled basement moisture with various methods, some more effective than others. Today, with liquid rubber concrete foundation and basement sealant – indoor, we have a modern, efficient, and DIY-friendly option that outshines many traditional approaches. It’s about making an informed choice for your home.

Flexibility and Durability

One of the most significant advantages of liquid rubber is its unparalleled flexibility. Unlike rigid cementitious coatings or paints that offer little give, liquid rubber boasts incredible elongation—up to 900% or even 1800% for some products. This means it can:

- Bridge Future Cracks: As your foundation naturally settles and experiences minor movements, liquid rubber stretches and contracts with it, preventing new hairline cracks from forming in the waterproof barrier. This is a game-changer for long-term performance.

- Resist Peeling and Flaking: Traditional paints or sealers often fail when hydrostatic pressure builds behind them, causing them to bubble, peel, and flake. Liquid rubber’s flexibility and strong adhesion help it resist these forces, maintaining an intact waterproof membrane for years.

Ease of Application and Safety

The DIY home improvement market saw a 4.2% increase in sales in 2017, reflecting a trend towards homeowners taking control of their projects. Liquid rubber concrete foundation and basement sealant – indoor fits perfectly into this trend:

- DIY Application: It’s designed for easy application by homeowners using standard tools like rollers or brushes. This eliminates the need for specialized equipment or professional contractors for many common moisture issues.

- Water-Based Cleanup: Being water-based, cleanup is simple with soap and water, avoiding the need for harsh, chemical solvents.

- No Harsh Solvents, VOC-Free: This is paramount for indoor air quality. Liquid rubber sealants are typically non-toxic and VOC-free, meaning they don’t release harmful volatile organic compounds into your home. This makes them safe for use in confined basement spaces, protecting your family and pets.

For more insights into choosing the right product for your basement, check out our best foundation sealants guide.

Cost-Effectiveness: DIY Savings

Homeowners are always looking for ways to get the most value for their investment, and liquid rubber delivers.

- Cost of Materials vs. Labor: While the materials themselves represent an investment, the ability to apply liquid rubber concrete foundation and basement sealant – indoor yourself offers significant labor savings. Professional basement waterproofing services can range from $4,000 to $8,000 or more, especially in our service areas like Bryn Mawr and Quakertown. By opting for a DIY liquid rubber solution for moisture prevention, you’re primarily paying for the product, not the costly labor.

- When to Call a Professional: It’s important to know when DIY is appropriate and when to call in the experts. For minor dampness, condensation, or small cracks, liquid rubber is an excellent DIY solution. However, if you’re experiencing significant structural issues, persistent active leaks, or major water intrusion, it’s always best to consult with professionals like us. We have the specialized equipment to identify the root cause of leaks and offer comprehensive, guaranteed solutions.

To understand the financial aspects further, read about the cost of waterproofing basement walls from the inside.

Frequently Asked Questions about Indoor Basement Sealants

We get a lot of great questions from homeowners in places like Ardmore and Collegeville about waterproofing their basements. Let’s tackle some of the most common ones regarding liquid rubber concrete foundation and basement sealant – indoor.

What surfaces can I apply liquid rubber to in my basement?

The versatility of liquid rubber is one of its strong suits! You can apply liquid rubber concrete foundation and basement sealant – indoor to a wide range of common basement surfaces, creating a seamless waterproof membrane on:

- Concrete walls: Both poured concrete and concrete block walls.

- Cinder blocks: These porous surfaces benefit greatly from the sealing properties of liquid rubber.

- Insulated Concrete Forms (ICFs): Liquid rubber adheres well to ICFs, providing an additional layer of moisture protection.

- Wood: While less common for entire basement walls, liquid rubber can be applied to wood surfaces (e.g., cellar doors, wooden sections of foundation) to waterproof them.

- Masonry: Including brick and other masonry surfaces.

The key is always proper surface preparation to ensure optimal adhesion, regardless of the material.

How long does liquid rubber sealant last?

The long-term durability of liquid rubber concrete foundation and basement sealant – indoor is impressive, especially when applied correctly. Many products offer warranties, with some specifically for interior basement applications providing a 3-year warranty, and exterior foundation products often boasting 10-year warranties.

Factors affecting its lifespan include:

- Surface Preparation: A clean, properly prepped surface ensures maximum adhesion and longevity.

- Application Thickness: Applying the recommended number of coats to achieve the specified dry film thickness is crucial for durability.

- Environmental Conditions: While indoors, consistent high humidity or extreme temperature fluctuations can play a minor role over decades.

- Underlying Issues: If the sealant is constantly fighting severe hydrostatic pressure due to unaddressed exterior drainage problems, its lifespan might be impacted.

The good news is that liquid rubber sealants require minimal maintenance. Regularly inspecting your basement for any signs of new moisture or damage will help you catch and address issues early.

Can liquid rubber stop active water leaks?

This is a crucial distinction. Liquid rubber concrete foundation and basement sealant – indoor is an excellent moisture barrier and a fantastic preventative measure against water intrusion, but it is generally not designed to stop active, flowing water leaks. Think of it as a robust rain jacket, not a dam.

If you have water actively streaming or steadily seeping into your basement, especially in areas like Bristol Township or Middletown Township where we see various soil conditions, the first step is to address the source of that water from the exterior. This often involves:

- Addressing Exterior Drainage: Ensuring your gutters are clean and extended, and that the ground around your foundation slopes away from the house.

- Repairing Significant Cracks: Large, structural cracks might require more intensive repair methods before a sealant can be effective.

Once the active water flow has been stopped and the source addressed, then liquid rubber concrete foundation and basement sealant – indoor becomes an ideal solution for moisture-proofing the interior walls, creating that final barrier against any lingering dampness or vapor drive. If you have significant water issues, we strongly recommend a professional inspection to identify the root cause and implement the most effective solution.

Conclusion

We’ve explored how liquid rubber concrete foundation and basement sealant – indoor offers a modern, effective, and accessible solution for maintaining a dry and healthy basement. From its elastomeric properties that bridge cracks and prevent moisture, to its non-toxic, VOC-free composition that ensures safety for your family, liquid rubber stands out. It’s a DIY-friendly project that empowers homeowners to take control of their indoor environment, leading to peace of mind and improved home value.

However, we understand that not all basement problems are created equal. For major structural issues, persistent active leaks, or when you need to pinpoint hidden leak sources with specialized equipment, the experts at Basement Waterproofing Scientists are here to help. With over 30 years of combined team experience serving Pennsylvania, New Jersey, and Delaware, including areas like Willow Grove, King of Prussia, and Horsham, we offer professional inspections and guaranteed solutions. We specialize in using advanced techniques to identify the exact source of leaks, allowing us to fix them more efficiently and effectively.

Don’t let a damp basement dampen your spirits. Whether you’re tackling a DIY project with liquid rubber or need the expertise of seasoned professionals, we’re dedicated to helping you achieve a permanently dry basement.

Learn more about our exterior foundation waterproofing services.