Transform Your Basement with a Flawless Finish

Epoxy flooring in basement installations are the go-to solution for homeowners seeking a durable, waterproof surface that looks amazing and lasts for decades. If you’re dealing with moisture issues, want to create usable living space, or simply upgrade from cold concrete, epoxy offers superior performance. Unlike carpet or wood, which are destroyed by water, epoxy thrives in damp conditions.

Key Benefits of Basement Epoxy Flooring:

- Waterproof protection – Creates an impermeable barrier against moisture.

- Exceptional durability – Lasts 10-20 years in residential settings.

- Mold and mildew resistance – Non-porous surface prevents growth.

- Easy maintenance – Simple sweeping and occasional mopping is all it takes.

- Improved aesthetics – Available in solid colors, metallics, and decorative flakes.

- Cost-effective – More affordable long-term than most flooring options.

I’m Darin Garvey, and with over 30 years of experience in basement waterproofing, I’ve seen how epoxy flooring in basement applications transform unusable spaces. My team at Basement Waterproofing Scientists has helped hundreds of Philadelphia-area homeowners create dry, healthy basements with proven epoxy installation techniques.

Epoxy flooring in basement terms explained:

The Unbeatable Benefits of Epoxy Flooring for Basements

Basement floors need to be tough. Epoxy flooring in basement installations deliver a surface that handles water damage, heavy impacts, and daily wear and tear with ease. Beyond looking great, epoxy offers incredible durability, waterproof protection, and simple maintenance, improving your home’s value and air quality.

For comprehensive information about all your basement flooring choices, check out basement floor coatings.

Superior Durability and Strength

Originally designed for industrial settings, epoxy brings commercial-grade strength to your home. A residential epoxy floor lasts 10 to 20 years, far outliving concrete paint. By chemically bonding with the concrete, it creates a new, solid surface that resists scratches, withstands heavy foot traffic, and protects the underlying slab. It even fills hairline cracks as it cures, resulting in a smooth, seamless finish.

A Powerful Defense Against Moisture and Mold

Basements are prone to moisture, which is where epoxy flooring in basement environments truly excels. It creates a waterproof barrier that moisture cannot penetrate. This non-porous surface means spills or humidity stay on top for easy cleanup. More importantly, this prevents mold growth by eliminating the damp, porous conditions it needs to thrive. This leads to improved indoor air quality and can even help with radon gas mitigation by sealing the concrete. For more on waterproofing, visit epoxy basement floor waterproofing.

Effortless Cleaning and Maintenance

Epoxy’s seamless surface has no grout lines or cracks to trap dirt, keeping your basement cleaner and more dust-free. Spills, even oil and chemicals, wipe away easily without staining. Regular maintenance is just simple sweeping and mopping with mild soap and water. Compared to scrubbing tile grout or deep-cleaning carpets, epoxy is the undisputed low-maintenance champion, giving you more time to enjoy your space.

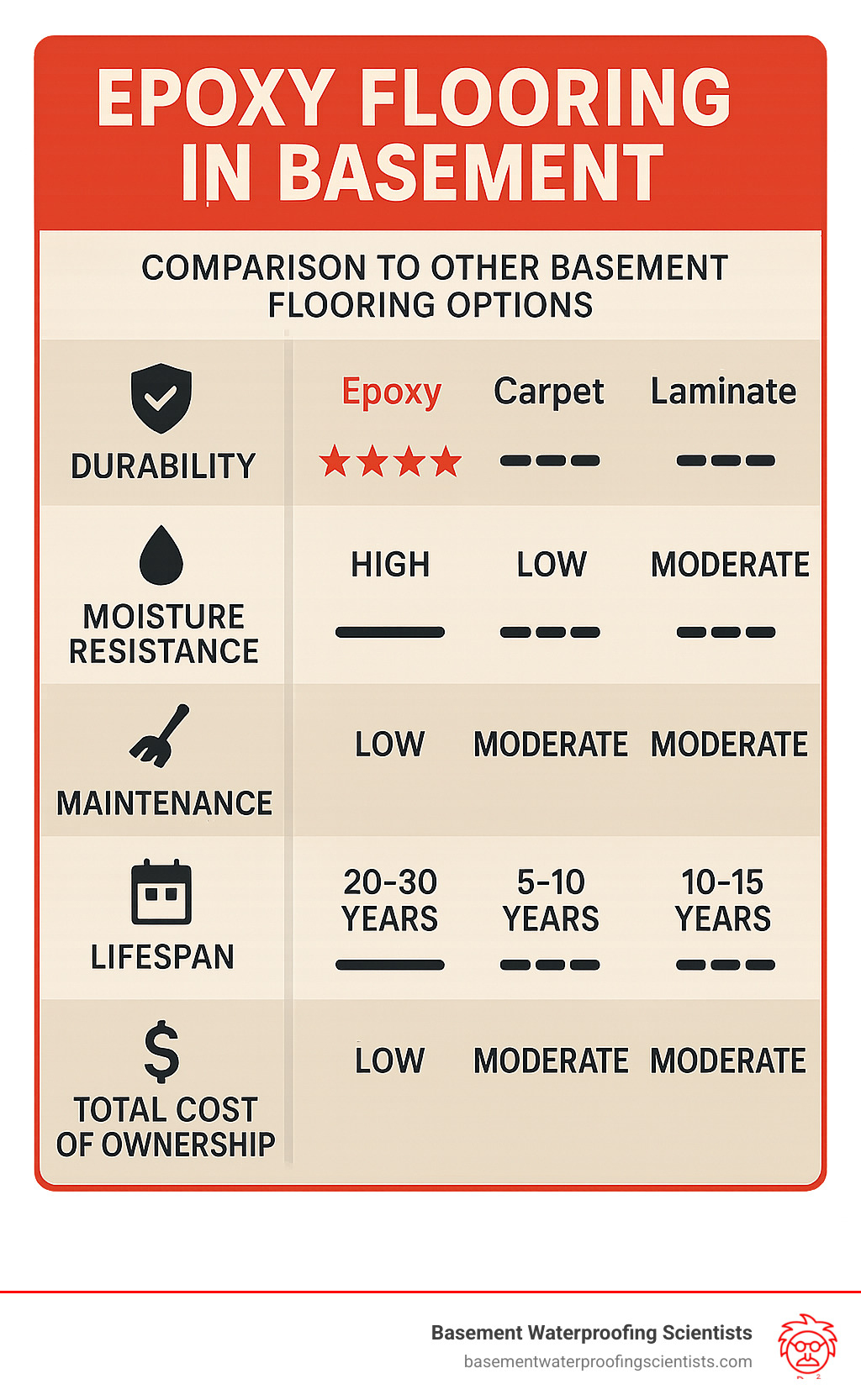

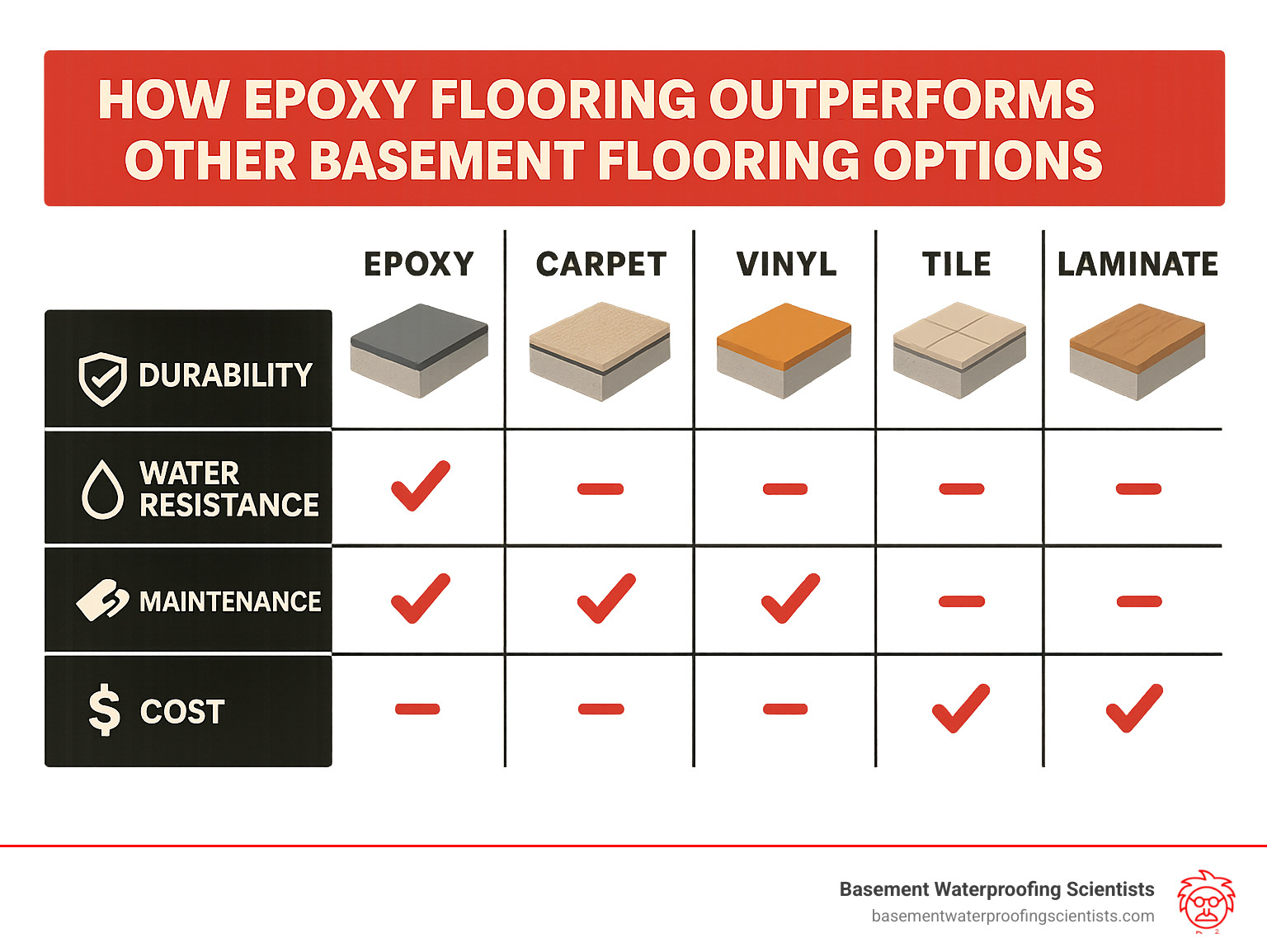

How Epoxy Flooring Outperforms Other Basement Flooring Options

Choosing the right basement flooring is critical, as basements have unique challenges like moisture that can ruin standard materials. Epoxy flooring in basement installations consistently outperform traditional options in every category that matters for a below-grade space.

Why Traditional Flooring Fails in Basements

Many common flooring materials are destined to fail in a basement environment due to a few key weaknesses:

- Moisture Vulnerability: This is the biggest issue. Carpet acts like a sponge, trapping moisture and leading to mold and odors. Laminate and wood will swell, warp, and buckle from humidity alone. Vinyl planks, while water-resistant, can trap moisture underneath, creating hidden mold problems.

- Durability Issues: Concrete paint is a temporary fix that chips and peels under normal foot traffic. Vinyl can be easily dented or gouged.

- Maintenance and Health Concerns: Tile is waterproof, but its porous grout lines stain easily and harbor bacteria and mold. Carpet traps dust, dander, and other allergens, negatively impacting air quality.

How Epoxy Solves Every Basement Flooring Problem

Epoxy flooring in basement environments is the definitive solution to these common pitfalls. Its seamless, non-porous surface creates a true waterproof barrier, eliminating the risk of moisture damage and mold growth. Allergens and dust have nowhere to hide and are easily swept away. With industrial-grade durability and a 10-20 year lifespan, epoxy is more cost-effective over time than materials that require frequent cleaning, repair, or replacement. It’s not just a covering; it’s a permanent upgrade to your basement.

Your Guide to Installing Epoxy Flooring in a Basement

Properly installing epoxy flooring in basement spaces is crucial for a long-lasting finish. Whether you DIY or hire a professional, success depends on meticulous preparation and careful application.

Essential Tools and Materials for a DIY Project

Gathering the right tools is the first step. You will need:

- Epoxy coating kit (resin and hardener)

- Concrete patch/filler and a degreaser

- Diamond grinder (preferred) or etching solution for surface prep

- Squeegee, paint roller with extension pole, and a mixing bucket

- Power drill with mixing attachment

- Spiked shoes to walk on wet epoxy

- Protective gear: respirator mask, chemical-resistant gloves, and safety glasses

Critical Preparation for a Lasting Finish

Preparation is the most important phase and cannot be rushed. A failed floor is almost always due to poor prep work.

- Moisture Test: Tape a plastic sheet to the floor for 24-48 hours. If moisture appears underneath, you must address the underlying water issue before proceeding. Epoxy requires a completely dry slab.

- Clean and Degrease: Thoroughly clean the floor to remove all dirt, oil, and contaminants that could prevent the epoxy from bonding.

- Repair Cracks: Use a concrete filler to patch any large cracks or holes. Epoxy will fill minor hairline cracks on its own.

- Grind or Etch: This step creates a “surface profile” for the epoxy to grip. Mechanical grinding is the best method. For more details, see our guide on Applying Epoxy Paint to Concrete Floor.

- Dry Completely: Allow the floor to dry for at least 48 hours after any wet prep.

The Step-by-Step Application Process

With prep work complete, you can begin application. Mixed epoxy has a limited working time (pot life), so work in manageable batches.

- Mix Components: Precisely mix the resin and hardener according to the manufacturer’s instructions using a drill attachment.

- Apply Base Coat: Cut in the edges with a brush. Pour the epoxy on the floor, spread it with a squeegee, and then back-roll for a uniform coat.

- Broadcast Flakes (Optional): If using decorative flakes, toss them onto the wet base coat immediately.

- Apply Topcoat: After the base coat cures (10-14 hours), sweep off loose flakes and apply a clear topcoat for durability and shine. Consider adding a non-skid additive.

- Cure: Allow the floor to cure. It can typically handle light foot traffic in 24 hours, but wait 5-7 days for a full cure before placing heavy items. For a detailed walkthrough, see How to Epoxy a Basement Floor.

Safety First: Working with Epoxy Materials

Epoxy materials require respect. Ensure critical ventilation by opening windows and using fans. Always wear your protective gear, including a respirator, gloves, and safety glasses. Choose low-VOC formulations when possible for better air quality. For more on safety, consult guides on Essential protective gear.

Longevity, Maintenance, and Troubleshooting Your Epoxy Floor

With proper installation and care, your epoxy flooring in basement will offer years of performance with minimal maintenance. Understanding its lifespan, finish options, and potential issues will help you keep it looking its best.

Lifespan and Available Finishes for Your Epoxy Flooring in Basement

A professionally installed epoxy flooring in basement lasts 10 to 20 years, making it a smart long-term investment. Beyond its longevity, epoxy offers a wide range of aesthetic choices:

- Solid Colors: Offer a clean, classic look in any shade.

- Metallic Finishes: Create stunning, marble-like 3D effects.

- Decorative Flake Systems: Add texture and color while hiding imperfections.

- Quartz Sand Floors: Provide maximum durability and a textured finish for high-traffic zones.

You can also choose between high-gloss or matte sheens and even create custom patterns. For ideas, you can Explore epoxy floor paint colors.

Solving Common Problems with Epoxy Flooring in Basement

Most epoxy issues are preventable with proper installation, but here’s how to identify and address them:

- Peeling or Delamination: This is the most serious issue, where epoxy lifts from the concrete. It’s almost always caused by moisture in the slab or inadequate surface preparation. The fix requires grinding down the affected area and reapplying the coating to a properly prepped surface.

- Bubbles or Fish Eyes: These small craters are caused by air escaping the concrete (outgassing), high humidity, or surface contamination. Proper prep and climate control during application prevent this.

- Scratches: While highly resistant, scratches can occur. A high-quality urethane topcoat is the best defense. An anti-slip additive can also help protect the surface.

Prevention is key. Professional installation ensures the surface preparation is done correctly, leading to a durable, trouble-free floor.

Frequently Asked Questions about Basement Epoxy Flooring

Homeowners often have questions when considering epoxy flooring in basement projects. Here are answers to the most common inquiries.

Is epoxy flooring slippery in a basement?

A high-gloss epoxy finish can be slippery when wet, similar to tile. However, this is easily solved by adding anti-slip additives to the final topcoat. These fine particles create a textured surface that provides excellent grip without compromising the floor’s appearance, ensuring safety in potentially damp basement environments.

Can you put epoxy over a cracked or damp concrete floor?

Epoxy can fill minor hairline cracks, but larger cracks require repair first. The most critical factor is moisture. Epoxy must be applied to a completely dry concrete slab. If your basement has active leaks, high humidity, or hydrostatic pressure, these water issues must be professionally resolved before application. Applying epoxy to a damp floor will cause it to fail, peel, and bubble.

How much does it cost to epoxy a basement floor?

The cost for epoxy flooring in basement installations typically ranges from $3 to $12 per square foot. The final price depends on the floor’s condition, the size of the basement, and the type of epoxy system chosen (e.g., solid color vs. metallic). While the initial investment may be higher than paint, epoxy’s 10-20 year lifespan makes it a highly cost-effective solution long-term. If underlying waterproofing is needed first, that separate investment protects your foundation and ensures the flooring lasts.

Conclusion: A Smart Investment for a Dry and Beautiful Basement

Choosing epoxy flooring in basement installations is a long-term investment in your home’s functionality, health, and value. It is the only solution that combines industrial-strength durability, stunning aesthetics, and an impermeable barrier against moisture and mold. Its 10-20 year lifespan and low maintenance make it one of the most cost-effective flooring choices you can make.

However, even the best epoxy floor will fail if applied over a damp foundation. At Basement Waterproofing Scientists, our 30 years of expertise is in creating the dry, stable foundation necessary for any successful flooring project. We use specialized equipment to identify and repair leak sources, ensuring your investment is protected by our lifetime guarantee.

If you’re tired of cold, damp concrete and ready to transform your basement into a beautiful, functional space, epoxy flooring in basement environments is the perfect solution. It’s durable, attractive, and practical enough for any use.

Ready to create a dry foundation for your stunning new floor? Explore our basement floor coating solutions and learn how we can help.