Why You Can’t Ignore Cracks in Your Cinder Block Wall

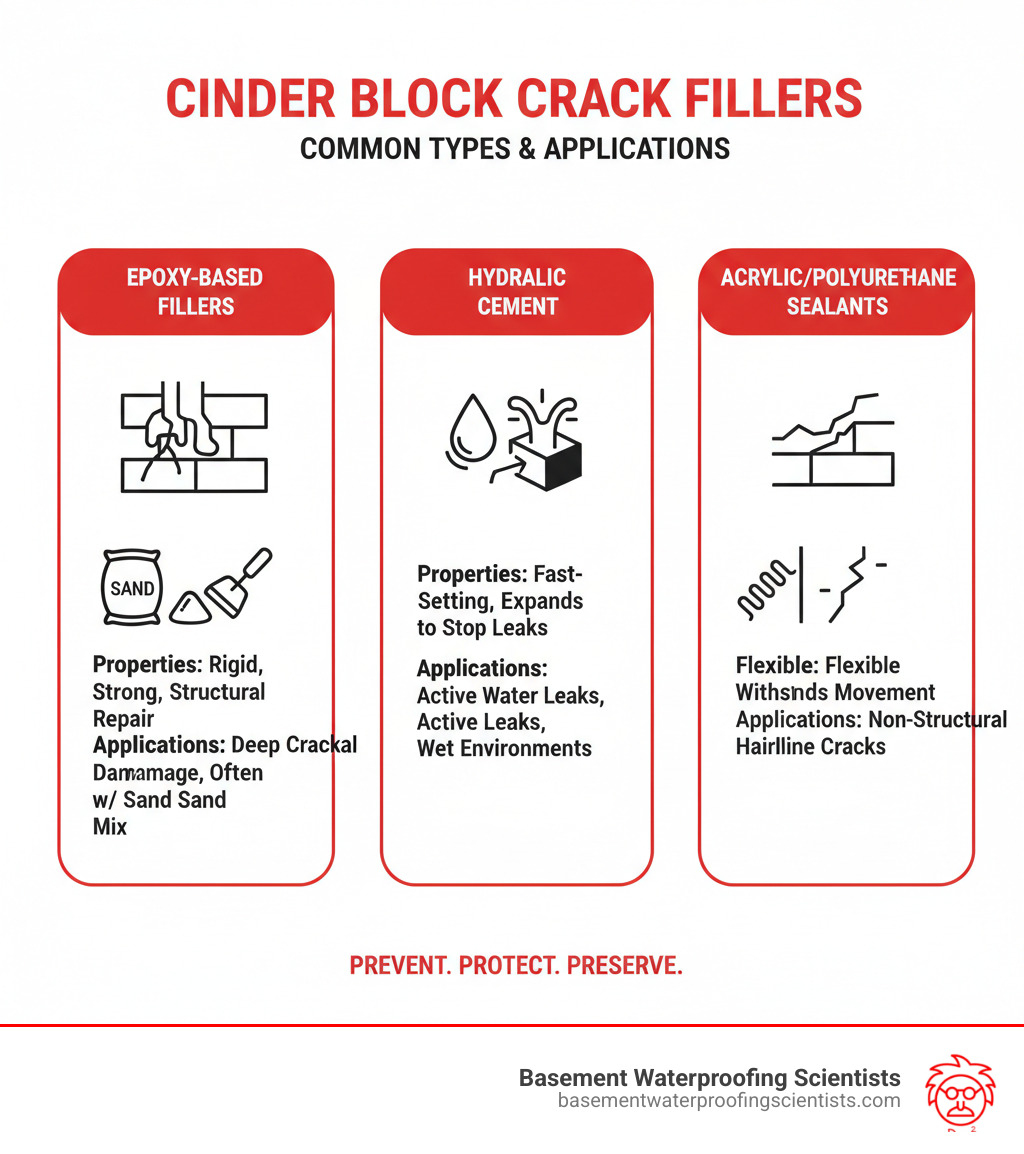

When you spot cracks in your basement or garage, finding the right cinder block crack filler is the first step. Common fillers include strong epoxy for structural issues, fast-setting hydraulic cement to stop active water leaks, and flexible polyurethane or acrylic sealants for minor hairline cracks.

Cinder block walls are strong, but cracks are a sign that something needs attention. Ignoring them can lead to bigger problems like water leaks, structural damage, or even pest infestations. Understanding the type of crack helps you choose the right fix. A small crack might need a simple filler, while a larger one can signal a deeper issue.

I’m Darin Garvey, and at Basement Waterproofing Scientists, I’ve spent years developing solutions for dry, safe basements. My expertise includes identifying and addressing all types of foundation issues, including those requiring a reliable cinder block crack filler.

Cracks in cinder block walls are more than an eyesore; they’re a message that your home needs attention. Ignoring them can lead to a cascade of costly problems.

First, cracks can compromise your home’s foundation integrity. They indicate that external forces are weakening the structural stability of your walls. A small crack can also become a gateway for water intrusion, leading to dampness, mold, and deterioration of the blocks themselves. Efflorescence (a white, powdery residue) is a common sign of water seepage.

Beyond water, cracks can invite pests like insects and rodents. They also create a pathway for radon gas penetration. Radon is a naturally occurring radioactive gas that can enter your home through foundation cracks, posing a serious health risk. Sealing these breaches is critical.

The long-term implications are significant. A hairline fracture can widen, leading to bowing walls, structural instability, and a decrease in your home’s value. Repairing these issues early is always more affordable than waiting until they become critical.

Understanding the Cracks: What Is Your Wall Telling You?

Cracks in your cinder block wall are symptoms of specific underlying issues. For over 30 years, we’ve learned to diagnose the cause before recommending a treatment. Most cracks are a reaction to forces acting on your foundation.

The most common culprits are foundation settlement (shifting soil), hydrostatic pressure (water-saturated soil pushing against walls), soil expansion (clay soils swelling and shrinking), and even invasive tree roots. The pattern of the crack tells a story about the forces at work. For more on how these issues appear externally, see our resources on exterior foundation cracks.

Vertical and Hairline Cracks

Thin, vertical cracks are usually the least worrisome. They are often caused by the natural shrinkage of concrete and mortar as they cure. Minor settlement can also create these thin lines. If the crack is narrow and not widening over time, it’s likely not a structural emergency.

These cracks often have DIY repair potential with a quality cinder block crack filler. We recommend monitoring cracks for a few months to ensure they are stable. If the crack remains unchanged, a simple seal will work. Our guide to sealing small foundation cracks can walk you through the process.

Diagonal (Stair-Step) Cracks

A crack that zigzags along the mortar joints in a stair-step pattern indicates a more serious issue: differential settlement. This means one part of your foundation is settling faster than another, creating uneven stress. It can also be caused by mortar joint failure as the mortar deteriorates over time.

Stair-step cracks signal an ongoing foundation problem that needs more than a surface fix. If the crack is wider than 1/8 inch, it’s time for a professional assessment. Filling it with a cinder block crack filler is like putting a Band-Aid on a broken bone—it hides the symptom without addressing the cause, and the crack will likely reappear.

Horizontal Cracks

If you see a horizontal crack, call a professional immediately. This is an SOS from your wall. Horizontal cracks are the most serious crack type and indicate bowing walls caused by intense external pressure from soil and water.

When hydrostatic pressure or expansive soils push against the wall, it can begin to bow inward, and the horizontal crack is the point of failure. This is not a DIY project. An immediate inspection is required to assess the damage and determine the correct structural repair, which may involve advanced techniques like wall anchors or carbon fiber reinforcement, not a simple surface patch.

Choosing the Right Cinder Block Crack Filler for Your Wall

Not all cracks are equal, and neither are the fillers used to repair them. Selecting the right cinder block crack filler is a critical decision. The best filler depends on the crack’s type, width, and whether it’s structural or leaking water.

Let’s break down the main types of fillers and their uses:

- Epoxy-based fillers offer high strength but low flexibility, making them ideal for rigid, permanent repairs on structural cracks.

- Hydraulic cement is a fast-setting, expanding cement that stops active water leaks, perfect for wet conditions.

- Flexible sealants (polyurethane and acrylic) have high flexibility, making them best for non-structural hairline cracks that may experience movement.

- Acrylic patching compounds are ready-to-use fillers for cosmetic repairs and small, non-structural cracks up to 1/4 inch.

For more help choosing the right material, our guide to the best foundation crack sealants offers additional insights.

Epoxy-Based Fillers

When a repair needs to be as strong as the original wall, we use epoxy-based fillers. These products provide incredible structural strength and create a rigid, permanent repair. Epoxy comes as a two-part mixture (resin and hardener) that you combine before application.

For larger cracks in cinder blocks, we recommend mixing the epoxy with sand (e.g., ElastiPoxy™ Joint & Crack Filler). This creates a robust filler that bridges large gaps and cures to a texture similar to mortar. It’s trowel-applied into the crack for a solid fill.

Traditional epoxy injection kits are not suitable for cinder blocks. The hollow cores of the blocks would cause the epoxy to run out without sealing the crack. Instead, a trowel-applied epoxy-sand mixture ensures the crack is properly filled.

Cementitious Fillers (Hydraulic Cement)

For active water leaks, hydraulic cement is a lifesaver. This unique cinder block crack filler is designed to stop flowing water instantly. It’s water-activated and expands as it cures, locking into place and creating a watertight seal in just 3 to 5 minutes.

We use hydraulic cement for active leaks and in wet environments where other fillers would fail. Products like Rapid Set Water Stop and DRYLOK Fast Plug are reliable for these situations. However, hydraulic cement is rigid and has low flexibility. If the wall is subject to movement, a rigid patch may crack again. High-quality versions like SikaSet® Waterplug are shrinkage-compensated for better durability in static cracks. While it’s an excellent immediate plug, it may need to be part of a broader waterproofing strategy. Learn more from our page on concrete wall crack sealers.

Flexible Sealants (Polyurethane & Acrylic)

For non-structural hairline cracks, flexible sealants are the ideal cinder block crack filler. These polyurethane and acrylic materials are designed to move with your walls as they expand and contract, preventing the repair from re-cracking.

Their key benefit is flexibility for movement. Products like DRYLOK® Masonry Crack Filler and Sika Sikaflex Concrete Fix excel at sealing non-structural cracks that may shift with the seasons. These sealants also provide excellent waterproofing and are easy to apply with a standard caulk gun. Most are paintable, allowing the repair to blend seamlessly with the wall. For cosmetic issues, acrylic patching compounds like QUIKRETE® Concrete Patching Compound work well for spalls and small cracks, drying to a durable, weather-resistant finish. They are your go-to for keeping moisture out without worrying about minor wall movement. For more on comprehensive waterproofing, see our complete guide to waterproofing concrete block walls.

The 4-Step Cinder Block Crack Repair Process

You’ve identified your crack and chosen the right cinder block crack filler. Now it’s time for the repair. Following these steps ensures a lasting fix, not just a temporary cover-up.

Step 1: Surface Preparation is Key

A clean surface is crucial for proper adhesion. If you skip this, your repair will likely fail.

First, clean the crack with a stiff wire brush to remove all loose debris, dirt, and crumbling mortar. Next, ensure the area is dry, as most fillers require a dry surface to bond. If water is actively leaking, use hydraulic cement to stop the flow first.

For a stronger repair, you may need to widen the crack into a V-shape using a grinder or chisel. This gives the filler more surface area to grip. If your home is older, be aware of potential lead paint and take safety precautions. The EPA offers guidance on lead safety.

Step 2: DIY Application of a Cinder Block Crack Filler

With the wall prepped, it’s time to apply the cinder block crack filler. The method depends on the product.

- For two-part epoxies, mix the compounds exactly as directed. If adding sand, mix it in thoroughly.

- For flexible sealants in a tube, use a caulk gun.

- For thicker compounds, use a small trowel.

The key is to force the filler deep into the crack, not just skim the surface. Push it in firmly to fill the entire void. For more detailed tips, our basement wall crack repair guide is a great resource.

Step 3: Curing and Drying Time

Patience is essential. After applying the cinder block crack filler, you must let it cure. Always check the label for product-specific cure times.

- Hydraulic cement sets in minutes.

- Flexible sealants may be paintable in an hour but need up to 12 hours to fully cure.

- Epoxy fillers often require a full 24 hours.

Temperature and humidity can affect drying times. Colder, damp conditions slow the process. Don’t rush this step; a fully cured repair is a strong one.

Step 4: Finishing and Waterproofing

Once the cinder block crack filler has cured, it’s time for finishing touches.

First, smooth the surface with a wet putty knife or trowel for a professional look. Next, you can paint over the repair to match your existing wall color. Finally, consider applying a waterproof coating for an extra layer of defense against moisture. Waterproofing paints are only effective if the crack is properly repaired first. For more on protecting block walls, see our guide to waterproofing a block wall foundation.

When to Call a Professional Instead of Using a Cinder Block Crack Filler

While a DIY approach with a cinder block crack filler works for minor cracks, some situations demand a professional. Attempting to fix severe issues yourself can lead to greater damage and higher costs.

You should call a professional if you observe any of the following:

- Crack Width (Wider than 1/8 inch): A wide crack indicates significant stress that filler alone cannot fix.

- Horizontal Cracks: These are a sign of bowing walls from external pressure and require immediate structural intervention.

- Bowing or Bulging Walls: A visibly leaning or bulging wall is a critical structural problem.

- Active Water Leaks: Persistent water intrusion points to hydrostatic pressure issues that need a comprehensive waterproofing solution.

- Multiple Stair-Step Cracks: Numerous diagonal cracks suggest ongoing foundation settlement that needs a professional diagnosis.

- Cracks that are Widening or Lengthening: This is a clear sign of an active, ongoing problem.

Our team at Basement Waterproofing Scientists specializes in diagnosing and repairing these complex issues. We identify the source of the problem and provide permanent solutions. Learn more about our approach to basement wall crack repair.

Advanced Structural Repair Methods

For issues beyond the scope of a simple cinder block crack filler, we use advanced structural repair methods to stabilize your foundation:

- Carbon Fiber Reinforcement: High-strength carbon fiber straps are applied to the interior of a bowing wall to reinforce it against inward pressure.

- Wall Anchors: These systems use steel plates on the interior wall connected to an anchor in stable soil outside, pulling the wall back toward plumb and stabilizing it.

- Helical Tiebacks: Similar to wall anchors, these are screwed deep into the ground to provide strong anchorage for failing walls.

- Wall Replacement: In the most severe cases of deterioration, rebuilding the wall may be the only safe option.

A professional assessment is crucial to determine the right method for your home. We offer expert inspections to recommend the most effective, lasting solutions. For more information, visit our page on foundation repair and waterproofing.

Comparing Cost and Effectiveness of Cinder Block Crack Filler Types

When considering cinder block crack filler options, it’s important to weigh the initial expense against long-term effectiveness.

- DIY Cost vs. Professional Cost: DIY fillers are affordable, often under $50. Professional structural repairs, however, can run into the thousands because they address the root cause with specialized materials and labor. Our average cost for comprehensive basement waterproofing is between $4,000 and $8,000, providing a permanent solution.

- Long-Term Effectiveness: Patching a crack without fixing the underlying cause—like hydrostatic pressure or foundation settlement—is a temporary fix. The crack will likely reappear. A proper repair addresses both the symptom and its cause. DIY fillers are effective for cosmetic or minor, stable cracks but are not designed for structural problems.

Frequently Asked Questions about Cinder Block Repair

It’s normal to have questions about cracks in your cinder block walls. Here are answers to some of the most common concerns we hear.

Can I just paint over cracks in my cinder block wall?

No. Painting over a crack is a purely cosmetic fix that hides the problem without solving it. Paint cannot restore structural strength or stop water intrusion. Moisture and movement will cause the paint to peel or crack, leaving you back where you started. For a lasting solution, the crack must be properly cleaned and filled with an appropriate cinder block crack filler before painting.

How much does it cost to repair a crack in a cinder block wall?

The cost varies depending on the severity of the crack. For small, non-structural cracks, a DIY repair using a cinder block crack filler can cost under $50. However, serious structural cracks require professional repair. Advanced solutions like carbon fiber reinforcement or wall anchors can range from a few hundred to several thousand dollars. Our average cost for complete basement waterproofing, which often includes expert crack repair, is typically between $4,000 and $8,000.

Will cracks come back after being repaired?

If you only patch the surface without fixing the underlying cause, the crack will likely return. If the wall is under stress from water pressure or foundation settlement, a simple filler will eventually fail. A permanent repair must address the root cause, such as improving drainage or reinforcing the foundation. Our goal is to provide long-term stability, not just a quick fix.

Secure Your Foundation for Good

You’ve learned what cracks in your cinder block walls mean and explored the different cinder block crack filler options. The most important takeaway is knowing when to choose a DIY solution and when to call a professional.

Remember: choosing the right filler is about matching the product to the problem. A flexible sealant is great for a stable hairline crack, while an epoxy mixture provides structural strength. But the real key is recognizing when a crack signals a bigger issue. Horizontal cracks, bowing walls, or cracks wider than a nickel are not problems you can patch away. These are urgent messages that your foundation needs professional attention. Using a cinder block crack filler on a serious structural problem only hides the issue while it gets worse.

That’s where we come in. At Basement Waterproofing Scientists, we solve the problems that cause cracks. With 30 years of experience serving homeowners across Pennsylvania, New Jersey, and Delaware, we use specialized equipment to pinpoint the source of foundation issues and fix them right the first time. Our average cost for comprehensive basement waterproofing is between $4,000 and $8,000, and our repairs are backed by a lifetime guarantee.

We serve Philadelphia, Reading, Norristown, Pottstown, Bensalem Township, Upper Darby Township, and surrounding communities like Bristol Township, Middletown Township, Lansdale, Warminster Township, Springfield Township, Haverford Township, Radnor Township, Willow Grove, King of Prussia, Horsham, Exeter Township, Cumru Township, Ardmore, Bryn Mawr, Quakertown, Royersford, Conshohocken, Hatboro, and Collegeville.

Your home deserves a permanent solution, not a temporary fix. Protect your home with a professional foundation sealant solution by contacting us today for a free, no-obligation inspection and estimate. Let’s ensure your basement stays dry and your foundation remains strong.