Waterproof concrete, as its name implies, is concrete with a high resistance to water ingress. There is a growing demand for waterproof concrete in structures such as underground parking lots and internal wet areas of buildings, where exposure to high amounts of water is likely. We will delve deep into the composition, benefits, and applications of waterproof concrete, discussing its importance in modern infrastructure.

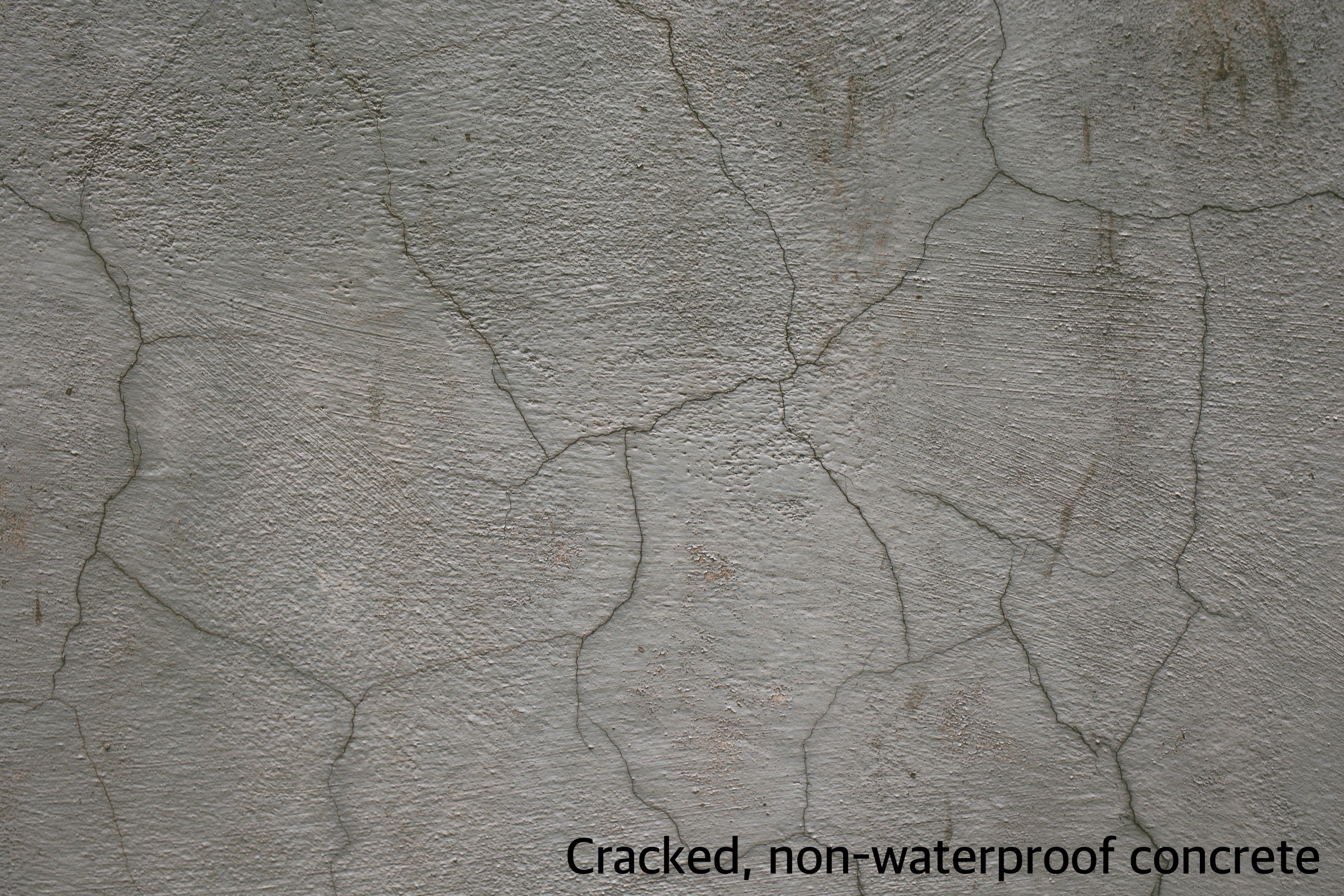

What Happens to Non-Waterproof Concrete?

Concrete is an essential building material, known for its strength and versatility in various structures, from buildings to bridges. However, traditional concrete, due to its porous nature, tends to absorb water, leading to issues such as mold growth and corrosion. These issues can cause cracks, compromising the integrity of the structure and escalating the cost of repairs. Thus, waterproofing concrete has become a standard practice in the construction industry to protect these structures.

There are two types of waterproof concrete that are most commonly used: integral waterproofing concrete and externally applied waterproof concrete. The choice between the two depends on the building design, cost considerations, and the expected level of exposure to water.

Integral Waterproofing Concrete

Integral Waterproofing Concrete involves the addition of admixtures to the concrete mix prior to placement. These admixtures react with the water in the mix, reducing the concrete’s porosity and enhancing its water resistance. An example of such an admixture includes crystalline chemicals that fill the pores and capillaries within the concrete, effectively preventing water ingress.

Externally Applied Waterproof Concrete

On the other hand, Externally Applied Waterproof Concrete relies on the application of a waterproofing membrane on the surface of the concrete slab. The membrane, which can be a liquid or a sheet, forms a continuous barrier, protecting the concrete from water contact. Proper application is crucial; the surface must be clean and free of cracks or other defects for the membrane to properly adhere.

Concrete Sealer

When it comes to waterproofing an already placed concrete slab, concrete sealers play a pivotal role. These sealers are substances that, when applied to the surface of concrete, seal off the pores, preventing moisture absorption. Concrete sealers come in various forms, such as epoxy coatings or penetrating sealers, which can protect against water, mold, mildew, and salts.

One of the primary challenges in the successful application of concrete sealers is ensuring a strong bond with the concrete surface. This is often achieved by applying a ‘primer’ coat first, allowing it to cure before applying a second coat. If cracks are present in the concrete, they must be repaired prior to sealing. Otherwise, the sealant may not bond properly, and water could find its way into these cracks. Therefore, inspecting the concrete slab for cracks and addressing them is a crucial step in the waterproofing process.

Why Waterproof Concrete?

Waterproofing concrete offers numerous benefits. In addition to mitigating the risk of water ingress, it reduces the potential for hydrostatic pressure build-up, which could otherwise lead to significant damage. Moreover, waterproof concrete helps in maintaining the appearance of structures, as it inhibits the growth of mold and algae, which can degrade the surface. Waterproofing can also enhance the lifespan of the structure, ultimately leading to cost savings.

The decision to waterproof concrete will largely depend on the structure’s proximity to the water table, the expected moisture content in the environment, and the potential for hydrostatic pressure. It’s important to consult with professionals who offer waterproofing services to assess your specific situation.

The world of waterproof concrete is continuously evolving, with new admixtures, concrete sealers, and application techniques being developed.

It’s essential for structure owners and builders to stay updated about the latest in concrete waterproofing to ensure that their structures are adequately protected.

Waterproof concrete plays a critical role in today’s construction industry, offering the necessary protection against moisture and enhancing the durability of structures. Despite the initial cost of waterproofing, the long-term benefits of reduced maintenance and extended structure life make it a worthwhile investment.